As Japan inundates America with video cassette recorders, facsimile copies, microwave ovens, minicomputers, semiconductors, fiber-optic cables, robots, numerically controlled machine tools, automobiles, farm machinery, stereo components, musical instruments, specialty steel, and countless other goods, the American business community is taking oddly contradictory views of the “Japanese challenge.”

On the one hand, American business leaders are paying increasing lip service to the virtues of Japanese management. The business press daily praises such innovations as “quality circles” and “lifetime employment,” which are said to result in greater worker commitment, fewer strikes, better quality of products. American management consultants repeatedly advise long-term investments in new products and processes seen as critical to the success of Japanese firms. American business schools are returning to the “basics” of production management and engineering, which are thought to underlie the ability of Japanese firms to respond quickly to new business opportunities. And American businessmen talk of new Japanese-style “understandings” between labor and management as well as profit-sharing schemes, joint research ventures, divestment programs, “theory Z.” Meanwhile, with each passing month, American business loses more ground. Bankruptcies soar, inventories expand, the percentage of industrial capacity being used declines. The American economy is grinding to a slow, painful halt.

With its own man in the White House, on the other hand, the American business community has found it awkward to place blame for its present troubles on the administration in Washington. Not even poor Paul Volcker, trying desperately to keep a rein on the money supply, fits the part of a national villain. The frantic search for scapegoats therefore has come to focus, as it so often does in times of national crisis, on a foreign villain, in this case Japan. American business is outraged by Japan’s tariff and nontariff barriers, which allegedly keep out American-made goods; by its “dumping” of products in the American market allegedly at prices far lower than those at which they are sold in Japan; and by Japan’s refusal to spend a larger percentage of its national income on defense. The “Japanese challenge,” which had been the extraordinary cleverness and ability of Japanese managers, is transformed into the devious, high-handed, and inscrutable policies of the Japanese government.

Both caricatures reveal far more about the American business community, and about American economic ideology, than they do about the Japanese. This is made evident in two new books that examine the relationship between Japanese business strategies and industrial policies. Taken together, these studies are valuable for understanding what is unique about the relations between business and government in Japan and the implications for America.

MITI and the Japanese Miracle, by Chalmers Johnson, presents an illuminating history of Japanese industrial policy, beginning with the creation of the Ministry of Commerce and Industry in 1925 and continuing through the postwar period when the Ministry of International Trade and Industry became central to Japan’s remarkable growth. Johnson shows that what appears to many Americans as the “art of Japanese management” is in fact a particular set of national industrial policies emanating from MITI. These business strategies and industrial policies have evolved together, complementing each other.

Neither could exist without the other. A bold American manager who tried to guarantee his workers permanent employment, and to invest for long-term growth instead of short-term profits, would soon find his company bankrupt and himself without a job. To do these things managers need the benefit of tax and credit policies that ease the burden on their firms during troughs in the business cycle. And they need subsidies to guide the flow of capital away from industries that are becoming less competitive in world markets and simultaneously to promote the development of industries that have a better chance to compete. Similarly, any inspired Washington bureaucrat who sought to pick industrial “winners” and steer investment to them would be doomed to failure without the benefit of Japan’s intricate network of strategic market information, which links Japanese firms, industries, banks, and key government agencies.

This match between business strategies and national industrial policies in Japan is not owing to Japanese character or culture. As Johnson shows, many of the practices that are considered peculiarly Japanese today were not conspicuous until relatively recently. Social and industrial harmony, for example, is a postwar phenomenon; the prewar years were marked by bitter struggles between factions in the army and navy, between the military and the large industrial groups called zaibatsu, between tenant farmers and landlords. Trade unions were suppressed by the authorities. Lifetime employment had little meaning in an industrial system in which most factory employees were young female textile operators whose working lives were two to three years, and in which nearly half the population were poor peasants.

National industrial policies were barely able to maintain stability after the financial panic of 1927, the invasion of Manchuria in 1931, the fascist attacks on capitalism in the 1930s, the war with China from 1937 to 1941, the Pacific war, the economic collapse of 1946, the post-Korean War recession of 1954. Many people will remember a time, not so many years ago, when “Made in Japan” was synonymous with cheap, shoddy workmanship. (During the 1950s, the American authorities filed charges against a toy manufacturer from the Japanese town of Usa, whose products bore the label “Made in Usa.”)

Advertisement

During the past twenty-five years, however, Japanese industrial policies have concentrated almost exclusively on transforming the Japanese economy toward industries with higher value. In 1959 Japan exported mainly products such as clothing, shoes, and toys from unskilled, labor-intensive industries. Throughout the 1960s, Japan pushed its economy into the more capital-intensive industries—steel, motorcycles, and ships—and industries derived from petrochemicals, such as plastics and fibers. By the mid-1970s, Japan could compete successfully in industries requiring complex machinery—automobiles, home appliances, and television receivers. By the end of the 1970s, Japan’s exports shifted once again, this time toward high-technology products—computers, robots, semiconductors, office equipment, and numerically controlled machine tools. Rather than try to preserve its industrial base at any given time, Japan’s industrial policies have sought to propel it into the future, while at the same time casting off older industries in which Japan’s competitive position is declining.

Johnson explains how MITI accomplished this by astutely using industrial policies to accelerate market forces in the Japanese economy, thereby pushing Japanese businesses into becoming more competitive internationally. Apart from politically sensitive farm products, MITI has employed tariff and nontariff barriers only to protect “infant industries” until they reach a size that is competitive internationally. By contrast, the United States has consistently used its tariffs, quotas, “orderly marketing agreements,” tax breaks, and bailouts of various kinds to protect older industries that have long since become uncompetitive in world markets. These policies have retarded change in the structure of the American economy.

In every advanced nation, for example, the textile industry has become less productive as it has shifted production to the less well-developed countries with low-paid labor. Anticipating this change, Japanese firms that were making cotton, rayon, and synthetic fibers have switched to different products in Japan, and transferred their textile manufacturing to other East Asian countries, often in joint ventures with foreign companies. The US has been engaged for over twenty years in a desperate attempt to protect its domestic textile industry against foreign imports. The cost to American consumers of the tariffs on clothes alone is estimated to be $1.9 billion a year.1

Another example: in 1958 Japan decided to close down its high-cost coal industry and to base its industrial expansion on imported fuel, especially oil. MITI’s subsequent policy of discouraging nonessential consumption by allowing oil prices to rise with world market prices prepared Japan to deal effectively with the oil shocks of the 1970s. By September of 1980, only fifteen months after the second big rise in oil prices plunged its international payments into deficit, Japan had a $938 million trade surplus. The United States, by contrast, controlled the price of domestic oil throughout the 1960s, thereby encouraging consumption and rendering America wholly unprepared to deal with the oil shocks.

Shipbuilding was a key industry for Japan in the 1960s. But changes in the world economy made the industry less competitive. Johnson describes how MITI therefore created a cartel in shipbuilding under special depressed-industries legislation passed in 1977. Consulting with the industry, MITI scrapped over 40 percent of existing shipbuilding capacity. The United States, however, continues to spend over $500 million per year, and provide over $6.3 billion in loans and loan guarantees, in order to prop up its ailing shipbuilding industry. 2

In high-technology industries, MITI has been careful to preserve domestic competition by giving firms equal access to research projects carried on jointly by government and business, such as the recent effort to build very large-scale integrated circuitry. Five major Japanese firms were involved in that project, and MITI provided all with information and support. The Japanese government is even willing to ask firms to bid for its contracts—as when Nippon Telegraph and Telephone invited American firms to compete for contracts for communications equipment.

By contrast, United States government research projects have tended to go to giant American firms without competitive bidding—as with 64 percent of the dollar volume of Pentagon contracts last year.3 Indeed, the Pentagon often regards competition as a threat to the stability of large defense contractors. Only American manufacturers are now allowed to bid on many defense contracts and even nondefense work is allotted exclusively to American firms. AT&T’s recent decision to award a large fiber-optics contract to its Western Electric subsidiary rather than to Fujitsu, the lowest bidder, was strongly supported by the Federal Communications Commission and the Pentagon.

Advertisement

Japanese firms get long-term financing from local banks, which in turn co-ordinate their loans with the Bank of Japan, the Ministry of Finance, and MITI. This allows the firms to drop their prices suddenly when faced with declining demand or temporary over-capacity. Rather than match these low prices, American firms have charged Japanese firms with unfair “dumping” and seek duties and other sorts of import barriers against them.

America’s steel industry, for example, for decades set prices in lock step with US Steel, the industry leader. When Japanese steel makers reduced their prices in response to the steel glut of the late 1960s, the US steel-making oligopoly was unwilling to do the same and it lobbied for protection. This lobbying paid off. The Japanese first agreed to “voluntary” restrictions on steel exports in 1968, renewed them in 1971, and then in 1977 accepted the infamous “trigger price” mechanism. Between 1966 and 1972, however, the Japanese steel industry invested heavily in more efficient plants, increasing its assets by more than 23 percent a year, and it became the world’s most efficient steel producer during the 1970s.

Once the US steel industry gained protection against Japanese imports, it actually reduced its capital expenditures to an average of 4 percent growth per year. But between 1966 and 1972 the eight largest US steel producers had a 3.8 percent average return on assets, as opposed to a 1.8 percent return for the five largest Japanese steel companies.4 The secret of Japan’s success was not “dumping,” but long-term financing. A similar story can be told about American automobiles and consumer electronics, both of which are now protected behind tariff walls or “voluntary” export agreements.

Nor does it make sense to argue that Japan’s low defense expenditures have been responsible for its remarkable growth. Had Japan’s overall rate of capital investment been very low, then the demands of defense might conceivably have retarded, or at least distorted, its economic development. But Japanese capital investment has, on average, exceeded 30 percent of its gross national product during the last two decades. This point is confirmed by the very high defense expenditures of South Korea and Taiwan which, when coupled with their high investment strategies, have had little or no impact on their economic performance. The truth is that US defense and aerospace expenditures during the last three decades have propelled the American economy into new industries like computers, semiconductors, high-density ceramics, robotics, fiber optics, lasers, and biotechnology. Without research and development, the American economy would be lagging even further behind.

Quite as dramatic as Japan’s growth has been the ability of some developing nations in Asia to use more and more complex manufacturing processes as the costs of transportation and communication have gone down. Japan anticipated this would happen and changed its own economy in order to meet it. In The Eastasia Edge, Roy Hofheinz, Jr., and Kent Calder show how this process transformed the economies of Japan’s less-developed trading partners—notably, South Korea, the Philippines, Taiwan, Hong Kong, and Singapore.

Hofheinz and Calder show that the economic and administrative arrangements of these nations have much in common with those of Japan, and this helps to explain why the process of industrial adjustment has been so rapid in the entire region. With each step in Japan’s evolution from textiles and toys, to steel and ships, to appliances and automobiles, and finally to high technologies, the other nations of the region have been one or two steps behind. By accelerating its own industrial evolution, Japan has helped to accelerate theirs. Within each nation, central banks have provided long-term financing for industries with good prospects for growth. Highly skilled bureaucrats in economic ministries have devised tax incentives, export financing, and subsidized research programs for the same industries. Powerful industrial groups, business associations, and general trading companies have gathered detailed intelligence on trends in world markets, which they share with the central banks and economic ministries. These vast networks of interlocking public and private bureaucracies are continually involved in strategic planning of their economies—planning focused on international competition.

Why have public policies in America retarded structural changes in the US economy instead of accelerating them, as in Japan and much of East Asia? The reason is that America’s declining industries typically have had far greater political power than emerging ones. The declining industries are so big and so old that entire cities or regions have come to depend on them—including a large number of suppliers, distributors, independent contractors, and service businesses, not to mention their own employees and shareholders. These declining industries have well-established political connections. Many of the emerging industries, by contrast, are small and new; relatively few people depend on them for a living. Jobs and investments endangered by international competition are far more potent political forces than those in industries that might one day become internationally competitive.

This disparity in the political power of declining and emerging industries has made it difficult for American politicians to formulate policies to achieve adjustment rather than protection. Thus far, the Reagan administration has shown itself no less susceptible to special pleading than its predecessors. The automobile industry benefits from a “voluntary” quota on Japanese imports, the savings and loan industry from a special tax break for “All Savers,” and the cable television, railroad, and oil and gas drilling industries from highly preferential tax depreciations. Right now, the administration is searching for new ways to help steel and automobiles.

All of these measures will help to preserve jobs in the short run, but they will further reduce America’s standard of living. If current trends continue, our national income within a generation will derive chiefly from supplying the world with raw materials like grain, coal, and timber; from assembling machines whose advanced components are manufactured elsewhere; and from distributing them. We will become a nation of extractors, assemblers, and retailers—poor by the standards of the rest of the industrialized world.

How do we shift from a politics of protection to a politics of adjustment? It is important to realize that neither Japan nor its East Asian neighbors offer a convincing answer. For the most part, they have dealt with the political realities of industrial decline by ignoring them. True, the guarantees of “lifetime” employment in Japan’s largest firms ease the pain of adjustment, but only for a fortunate one-third of Japanese workers; and the long-term financing provided by Japan’s banks eases the process of capital adjustment. But the burden of industrial change in Japan falls instead on subcontractors, women, and retired people, whose economic futures are highly uncertain. Many of these people leave the work force for considerable periods, especially when Japanese industry makes a major shift in production—from, say, the manufacture of color televisions to video cassette recorders. Others find temporary work in Japan’s retail stores, which make intensive use of labor. By and large, the people who bear the brunt of economic change in Japan do not have powerful trade associations to lobby for protection and subsidies, as do their American counterparts.

In any event, lobbying would get them nowhere. In Japan, the political coalition in favor of industrial change is too well entrenched to listen to the special pleadings of any industry but agriculture. The conservative Liberal Democratic Party has dominated the Diet since 1955, and the Diet merely approves as prime minister the man chosen by the party leaders through back-room political deals. The powerful economic ministries, in turn, are run by permanent administrative vice ministers. These leading bureaucrats, and the business leaders with whom they attended Tokyo University years before, form an impenetrable “old-boy” network which in effect governs Japan.

The network is reinforced by MITI’s various offices that deal with the corresponding officially sanctioned trade associations for each industry, as well as by many other policies that would, taken together, seem dangerously conspiratorial in the US: temporary exchanges of officials between state and private enterprise (for example, the posting of young MITI officers to trade association headquarters); formal “discussion groups” including people from the ministries and key industries; “administrative guidance,” in which government officials and representatives of banks and industries coordinate their activities unconstrained by law and lawyers.

Groups outside this system occasionally shout their disaffection. The violent demonstrations against the new Tokyo Airport and the government’s nuclear ship project, and the campaign against industrial pollution, are cases in point. But these are sporadic outbursts; they may result in some concessions, as when the city of Tokyo abruptly decided in favor of clean air; but they have little effect on the daily process of politics and economic administration in Japan.

Democratic politics is similarly ineffectual in the rest of East Asia. The South Korean government periodically declares all political opposition to be illegal. Those outside the ruling coalition are effectively disfranchised. Demonstrations expressing dissatisfaction, such as those at Kwangju in the spring of 1980, result in thousands being jailed. Singapore has blocked most political opposition even though its present government originated as a socialist opposition party. Taiwan has no free press, only a façade of multiparty representation. The Philippines have spent many years under martial law. In all of East Asia, there has not been a single legitimate change of party rule since the fall of the leftist Katayama cabinet in Japan in 1948.

Rapid industrial change is relatively easy to achieve when the leaders who plan it have no serious worries about politics. Many current discussions of industrial policy in America are based on the fantasy of an apolitical state in which the economy is “managed” by an elite group of strategists insulated from the special pleadings of declining industries. The neoconservative version of this fantasy assigns primary responsibility for managing the economy to the Federal Reserve, in conjunction with America’s largest corporations. The neoliberal version conjures up a revived Reconstruction Finance Corporation or tripartite industrial boards comprised of leaders from government, business, and organized labor. Both versions share a common ancestry in Herbert Hoover’s dream of an associationist state—a dream which came to brief fruition in Franklin Delano Roosevelt’s National Recovery Administration. Neither provides for direct review by, or accountability to, the people in the factories, towns, or regions that will be affected.

The books under review also fall prey to this managerial ideology. At the end of his study of MITI, Johnson suggests an economic “pilot agency” for the United States. “It is not clear that the United States could ever free such an apparatus from the constraints imposed by congress, the courts, and special interest groups,” Johnson warns, “but if economic mobilization becomes a national priority, then MITI will be an important institution to study and think about.” Hofheinz and Calder similarly suggest more insulated forms of policy making. Not even Japanese industrial policy is sufficiently immune from politics, in their view. “Interest groups have distorted public policy in Japan more than in any other Eastasian nation, although their impact on policy formation has not been so striking as it often is in the West.”

The effort to divorce industrial policy from politics in America is doomed to failure—or let us hope so. No doubt America must transform its economy. The heavy industries that have been dominant for the past fifty years—textiles, automobiles, steel, and petrochemicals—must be changed so that they can concentrate on the advanced “niches” within these industries—synthetic yarns, automobile components, steel mini-mills, and specially treated chemicals. And they must adapt to high technologies—using robots, fiber optics, lasers, biotechnologies, semiconductors. But a transformation of this magnitude must have broad public support. For unless the burdens of industrial change are shared equitably, those groups upon whom they disproportionately fall will resist change with every resource at their command; and they will prevail. That is the great virtue of our political system. Rather than a “constraint” on rational industrial policy making, the power of economic minorities in America to veto plans that will jeopardize their well-being is a bulwark against tyranny by the majority.

In America the “losers” must be compensated. They must be given generous job training, help in relocating, new industries within their regions in which they easily can gain employment at wages as high as they had before, generous unemployment compensation, insurance against bad health. The high costs of such measures will be seen as horrifying only by those blind to the necessity of building a more dynamic and just economy. The workers who are being threatened must be included in the process of industrial policy making itself. Anything less, and they will resist—and will have a right to resist.

The Reagan administration’s decisions to reduce all forms of public assistance and to try to stop inflation by means of harsh unemployment engineered by the Federal Reserve will merely harden resistance to economic change in this country. We can expect, therefore, that tariffs, quotas, Orderly Marketing Agreements, bailouts, and other protectionist policies will continue. To render them ideologically compatible with Reagan’s free-market rhetoric, however, they will be disguised as aspects of national defense. The Pentagon will urge America’s largest corporations to purchase their technologies from American manufacturers rather than from the Japanese so as not to become dependent on foreign suppliers. Defense needs will serve as a pretext for restricting imports of Japanese semiconductors. Tariffs on steel imports will be justified as essential to our national security. The Pentagon will announce a policy on “strategic” minerals. There will be much talk about “strategic” industries. The Defense Production Act of 1950, which gives the president authority to restrict imports for the sake of national defense, will be trotted out once again. Our old industrial base, meanwhile, may be preserved for a time, but our economy will stagnate.

We have much to learn from the Japanese. Above all, we can learn that the real choice is either protection of the national economy from world markets or rapid adjustment of the national economy to world markets. Either way, government will be intimately involved. But only adjustment will yield long-term prosperity.

The Japanese do not have much to teach us about politics, however. Our untidy, contentious political culture is a strength. It is, I think, capable of generating a collective commitment to productivity that is unsurpassed. The difficult question is whether the US will be able to construct an industrial policy that builds on that strength, rather than one that seeks to escape from it.

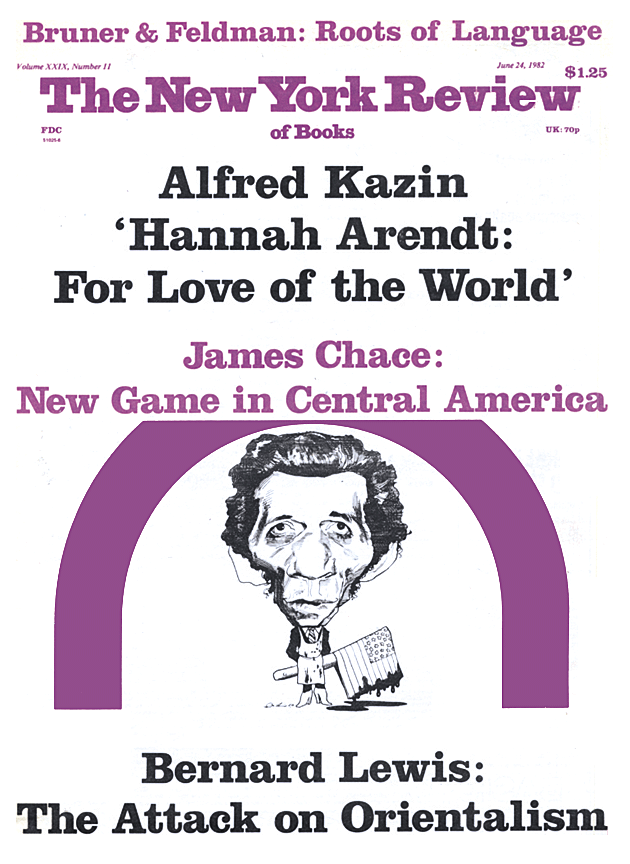

This Issue

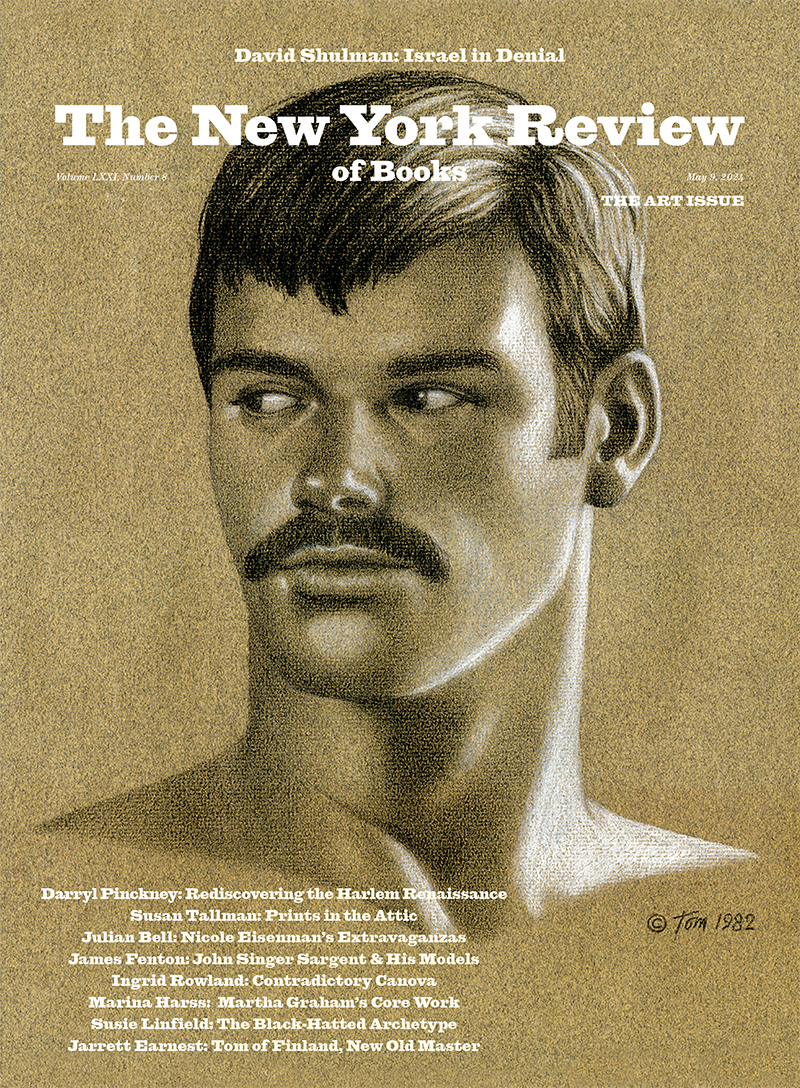

June 24, 1982

-

1

Morris E. Morkre and David G. Tarr, Effects of Restrictions on US Imports (US Federal Trade Commission; US Government Printing Office, June 1980). ↩

-

2

See Ira C. Magaziner and Robert B. Reich, Minding America’s Business: The Decline and Rise of the American Economy (Harcourt Brace Jovanovich, 1982), pp. 250-252. ↩

-

3

See Office of the Secretary of Defense, Military Prime Contract Awards: Fiscal Year 1981 (US Government Printing Office, 1982), p. 49. ↩

-

4

See Richard M. Duke, The United States Steel Industry and Its International Rivals: Trends and Factors Determining International Competitiveness (Federal Trade Commission, US Government Printing Office, November 1977). ↩