Guests and comrade workers, today we are not going to make a commemoration speech. That is, we are not going to recall achievements and successes scored by the Revolution. Neither are we going to recall past heroic events. It is not with words but with actions and work that one pays tribute to those who have given their all.

Neither are we going to deal today with problems of an international nature—about which we could and would like to say a great deal.

Today we are going to talk about our problems and difficulties [applause]; our setbacks rather than our successes, and we would like to make a series of analyses, even though we realize that a forum of this type is hardly the ideal place for either cold analysis or figures.

I don’t usually come to events such as this loaded down with papers. However, this time I had no alternative but to bring some papers with me [applause], since there are a lot of data and figures.

Let’s express the essence of our difficulties in the simplest possible terms.

Above all, we want the people to be informed. We want the people to understand. We want the people to gird themselves for battle. [Applause] This is because our problems will not be solved by means of miracles performed by individuals or even by groups of individuals. Only the people can perform miracles. [Applause]

So that you will better understand what I am going to explain, I would like to give you some data:

In 1958, on the eve of the triumph of the Revolution, Cuba’s population was 6,547,000. In 1970 it is estimated that the population will reach a figure of approximately 8,256,000. Our population has increased. We will know the exact figure after the census that is going to be made within a few weeks has been finished. This will be made very carefully to include everybody—that is, everybody but those who want to stop being a part of this conglomerate. [Applause]

For them, it will be the dolce vita and the consumer society. We will stay with other things that are harder but more honorable and worthy. [Applause] Though in the social order the real harshness of life is the lot only of cowards.

As I said before, our population has registered an increase of 1,709,000, of whom 844,000 are minors under working age and 188,000 are men and women over working age. Out of that 1,709,000, there are 1,032,000—that is, 60 percent—who are either under seventeen or over working age—women over fifty-five and men over sixty. In other words, 60 percent who do not participate in production.

Not counting those who are studying or are physically or socially disabled, the net increase in labor resources in these last twelve years has been 580,000. On the other hand, the needs of the economy for its new economic and social activities and the replacement of those who have reached retirement age call for 1,200,000 people.

What with our new labor resources and the number of unemployed that existed before the Revolution, we have been partly—only partly—able to meet our growing manpower needs.

Of course, at the beginning, in 1958, there were 686,000 unemployed. A large number of them are working today; others have reached an age that makes them no longer fit for work; and there remain 75,000 who, neither housewives, students, nor disabled, simply do not work. There are 75,000 of them.

These are the figures showing our population growth along these years and the make-up of the population.

According to estimates, how will things stand between 1970 and 1975? The situation will be even more serious. It is estimated that between 1970 and 1975 there will be a population increase of 660,000. Of these 660,000, the increase in minors—that is, the increase in those under working age—will be 280,000, the increase in people over working age will be 108,000, and the increase in people of working age will be 275,000. Thus, not counting those who will have to study and others who, for various other reasons, will not work, there will be a net increase in our labor resources of 167,000 people in the next five years.

Therefore, our problem in connection with manpower and the make-up of the population will continue to worsen in the next five years and will only begin to improve toward the end of the decade, close to 1980. It is estimated that the population increase between 1975 and 1980 will be 828,000. The increase in those under working age will be 160,000, 0the increase in those over working age will be 121,000, the increase in those of working age will be 550,000, and the net increase in our labor resources between 1975 and 1980 will be 535,000.

Therefore, the population make-up—you understand perfectly well what this is: it’s the composition of the population according to age we have just been talking about. This is what the trend will be for the next five years, and—I repeat—it will begin to improve from 1975 to 1980.

Advertisement

Now, then, this population make-up—this happens not only in our country but also in other countries that have experienced a population explosion, which means almost all of the underdeveloped countries—means that only 32 percent of the population is engaged in activities related to our economy. That is, less than a third of the population is engaged in furnishing goods or services. And that third includes those who are furnishing services that constitute investments for the future, such as public health services and education, and those engaged in services that are absolutely necessary to the defense of the Revolution and the homeland.

We must know these figures, first of all, in order to be fully aware of the situation, so we will know some of the obstacles that must be overcome.

I would like to point out that some of the services have increased, as a result of this population make-up and also as a result of elementary measures of justice that the Revolution had to adopt—measures which, in our opinion, could not be postponed. Social security, first of all.

A total of 379,842 retirement and survivors’ pensions have been granted since the triumph of the Revolution. That is, in the revolutionary process, a total of 379,842 people have had their right to these benefits recognized and these allotments have been paid to them.

In addition, a total of 193,260 survivors and retired people—most of whom had received pensions as low as under ten pesos a month—have had their allotment increased to a minimum of sixty pesos a month.

The outlay for social security services increased from 114.7 million pesos in 1958 to 320 million in 1970.

Public health services: In 1958 there were 8,209 workers in public health services. In 1969 the number increased to 87,646—87,646! Outlay for public health services, which in 1958 was 22.7 million pesos, increased to 236.1 million in 1969.

Outlay in education or in general services in education: In 1958 there were 936,723 people enrolled in schools throughout the country. A total of 2,289,464 enrolled in the 1969-70 school year—1,560,193 of them in primary education.

In 1958 there were 23,648 workers in public education. In 1969 the figure rose to 127,526.

The number of scholarships—15,698 in 1958—is now 277,505. This figure does not include the children in day-care centers and semiboarding schools.

In 1958 the outlay for public education was 77 million pesos. This figure rose to 290.6 million in 1969.

The number of beneficiaries of social security—that is, those who received new pensions and retirements—public health workers, workers in education, and scholarship students amounts to no fewer than 900,000 in 1970. And, if we add the men engaged in the defense of our country, the figure goes over 1,100,000.

Outlay for social security, public health, and education—three sectors—which was 213.8 million pesos in 1958, amounts to no less than 850 million for 1970. If we add the outlay for defense to these three sectors, the total comes close to 1.2 billion pesos a year.

I wanted to give comparative figures in pesos as well as comparative figures in people.

The average number of double rations distributed among industrial workers and workers in services, scholarship students, those in day-care centers and semiboarding schools, people mobilized for agricultural work and the sugar harvest, hospital patients, and combatants of the Ministry of the Revolutionary Armed Forces and the Ministry of the Interior amounted to approximately 2,250,000 per day.

Needless to say, such services must continue to increase. Suffice it to say that the number of working women increased from 194,000 in 1958 to close to 600,000 in 1970—which, naturally, creates new, extensive needs for not only children’s day-care centers but also semiboarding schools.

At the same time, notwithstanding the number of people working in education mentioned here and our expenditures for education, we must say that those needs are still far from being fully met—in both quantity and quality. There are still many cases of pupils who attend school only half a day, as a result of shortages of teachers and classrooms.

We will need 7,000 new primary school teachers a year from 1970 to 1975. Seven thousand new teachers must be graduated every year! Some of them will go to meet outstanding needs, another part will replace those who must retire because of old age, and the rest will constitute increases in both quantity and quality. Consequently, we need 35,000 new teachers in the next five years. For the same reasons, we will need 4,000 new junior high school teachers, 4,000 new junior high school teachers every year through 1975.

One thousand eight hundred new senior high school teachers will be needed every year. This means that we need to graduate—but this does not mean that we are going to graduate them, because, unfortunately, we can’t do this yet—12,800 new primary and junior and senior high school teachers every year—an aggregate of 64,000 in five years.

Advertisement

I believe that anyone can understand the significance that the solution or our failure to solve this problem has for this country. I believe that anyone can understand what a country will become or not become if it solves or fails to solve the problem of education. And the problem has to be solved in the conditions that I have explained to you, and all those resources have to be obtained from a population whose age make-up is worsening, with 32 percent—a percentage that will not grow in the near future—of the population producing all the resources.

By way of comparison, suffice it to say that the industrialized countries of Europe, including the socialist countries, with incomparably higher labor productivity, with much greater development of their productive forces, employ, or employed in the decade just past, approximately 45 percent of their total population. We are employing and will have to employ—not only for development, not only for providing for all of our unsatisfied needs, not only for our increasing needs—only 32 percent of the population. And, as we succeed in employing more women, more and more needs in the forms of schools, day-care centers, semiboarding schools, and the like will arise.

Under the Urban Reform Law, 268,089 families have been made home owners and do not have to pay any kind of rent; the value of that real estate is estimated at 3.5 billion pesos. In the same way, more than 100,000 families in rural areas who before the Revolution had to pay rent for their land have received the lifetime use of that land absolutely free.

The increase in the number of retired workers, free educational services and medical care, and the essential services of the nation’s defense, together with the savings in connection with home and land rentals, have caused the amount of money and savings accounts in the hands of the people to shoot up to 3 billion pesos.

A price policy to compensate for this imbalance—this will help us and also those abroad who are interested in such things to understand the reason for rationing—would have been nothing short of a ruthless sacrifice of those sectors of the population with the least income. This is quite plain: a price policy aimed at evening up the total amount of goods and services that the people have to purchase—the things that are distributed free of charge are not taken into consideration in this—on the one hand, and money, on the other, would have been nothing less than a ruthless sacrifice of that part of the population with the lowest income.

That policy could be employed in connection with luxury and nonessential goods and services, but never for necessities. This is how we feel about this problem, and we believe that the people feel the same way. [Applause]

Devaluation—or rather, the exchange of the currency, which was done in the early years—is a correct measure when applied against the bourgeoisie, but it would be despicable if enacted against the workers’ savings. [Applause] This is how we feel about it, and we believe the people feel the same way. [Applause]

This is just one of the complex problems of our economy that we must solve.

Now, then, how are these problems, such as the population make-up and the increase in essential and necessary services, translated…? Because I don’t believe there is a single person who doubts how essential it was to grant old-age pensions to men and women who had been exploited all their lives. What kind of a people would this be if it selfishly failed to repair such an injustice; what kind of a people would this be if it remained unmoved by the plight of cane cutters who, after laboring for thirty long years, ended up with a pension of only seven pesos a month?

I don’t believe there is a single Cuban who has the slightest doubt about the effort that has been made in connection with the health of the people, to remedy the tragic conditions in which millions of people in this country lived, where scores of thousands of families witnessed the death of their young ones—this could be figured mathematically—and I don’t believe that anybody, much less any of those who have had an opportunity to travel in the interior of the country, has the slightest doubt as to the absolute necessity of the medical services provided by the Revolution, whatever their price.

On the contrary, every time the people discuss this problem, they express the wish to have a polyclinic of such and such a size in the place where they live, or to have a doctor where they work and live, or at least to have one on duty during the night. We must say that, of the thousands of sailors in our merchant marine who traverse the oceans of the world and the thousands of fishermen in our fishing fleet, very few are on ships which we have been able to supply with a doctor to attend cases of accident and urgent sickness. To tell the truth, we are far from having taken care of that need.

We don’t believe there is a single Cuban who has any doubts about the essential and dramatic need of lifting this country out of the state of illiteracy and semiliteracy in which it finds itself. If 30 percent of us were illiterates, 95 percent of us were semiliterates. And we’ll still be paying the price of that illiteracy and semiliteracy for many years to come. We can see this; we have occasion to see this every time we find comrades in posts of leadership, in factories and other activities who, though full of the best intentions in the world, in many instances don’t have any more than a sixth-grade education.

We don’t know of anybody who, when discussing education, has told us that we should have made less of an effort in education, granted fewer scholarships, offered fewer jobs to teachers, and built fewer schools. What we do find all the time throughout the country are thousands upon thousands of persons who say that such and such a school is too small, that it is overcrowded, that a larger one should be built, that a double session has to be established, that a dining room should be provided. There are thousands upon thousands who say we need more and better teachers, more books and more school supplies, and there are towns where the people want to have junior and senior high schools. Moreover, there is a demand for more and more scholarships. This is because already no fewer than 60,000 pupils are being graduated from the sixth grade every year, and in the near future, if we succeed in winning the battle of education, no fewer than 150,000 should be graduated every year.

And I ask myself if the future of the children of this nation is only to reach the sixth grade, if the future of this people in the midst of a world that is undergoing a technological revolution at a terrific pace can be any future at all with a sixth-grade education as an average. Today a sixth-grade education is practically equivalent to illiteracy.

Therefore, despite all our outlays and efforts, what we find today is a tremendous demand for new outlays and new efforts.

And I don’t believe there is a single Cuban—we don’t believe there is a single revolutionary—who thinks that this country should have folded its arms in the face of that most powerful imperialist enemy ninety miles from our shores, an enemy that did not hesitate to use all means and weapons to destroy our Revolution. I don’t believe there is a single Cuban who thinks that, in the face of this enemy’s actions, in the face of every threat and danger, our people should have remained unarmed and defenseless. On the contrary, the vast majority of the people have learned how to use weapons, as they have realized that the number of permanent cadres and men would not suffice for the defense of the country if that enemy attacked.

In that essential task of the Revolution, it has been necessary to employ hundreds of thousands of men—we can say hundreds of thousands, though the number may be under 300,000—and scores of thousands of cadres. It is true that, just like our students, they take part in tasks of production in critical periods—that is, in periods of peak manpower demands in the countryside, as during the sugar harvest—but it is also true that, to the extent that our technological and high-school students have spent long months cutting cane, we’ll have to wait more years to have the technicians we need so urgently. And, to the extent that our soldiers have to spend months in the cane fields, we have had to sacrifice their combat preparation in case of war. Unfortunately, given the low level of our productive forces and our labor productivity, we’ll have to continue doing this.

These are realities imposed on us by the Revolution itself. However, we are not mentioning them as excuses and pretexts or as an explanation or the only explanation of our problems. We mention them simply as facts to serve as the basis for an over-all evaluation.

To all this we must add one more reality—one that weighs rather heavily—which is our own inefficiency, our inefficiency in the general work of the Revolution.

What does this conflict among the various needs posed by development result in? If we want to build a plant such as the one in Cienfuegos, with a capacity to produce half a million tons of nitrogenized fertilizers per year—fertilizers we are now importing, since what we produce here is not actually made here but is rather mixed of various elements we import—we will have to invest more than forty million dollars.

And the same thing is true of every other industrial plant and every item of machinery and equipment this country imports.

The conflicts stemming from the various needs posed by development, together with the supply of those essential resources, considering the age make-up of our population, plus the unquestionable inefficiency of all of us….

We have just finished waging a heroic battle, a battle that can truly be called heroic. The heroes of that battle are represented here. The people were the heroes of that battle, the battle for the ten million tons, both in the planting and in the harvesting. [Applause] And enough cane was cut to produce practically ten million tons, enough to have resulted in ten million tons if the industrial side of the sugar-making process had held up its end.

The people were heroes—not only in fulfilling that task, but even more so in deciding to cut every last stalk of cane, even when they knew that the ten million tons would not be reached. [Applause] And the people followed through on that. There is still a little cane left in Oriente Province, but we decided that it was no longer reasonable, from any point of view, to continue cutting after July 23.

Of course, we achieved a large increase in sugar production: more than four million tons over what was produced last year. This is a production increase that is a true record, one that will be really difficult to surpass—this doesn’t mean that someday we won’t produce more sugar, but it will be difficult to achieve such an increase in production again—especially if we consider what we have said about the age make-up of the population and the shortage of manpower, because there have been not only quantitative increases in our needs but also qualitative changes as well, because, in the past, hundreds of thousands of Cubans in our countryside had to work from fifteen to seventeen hours a day cutting cane with a machete and loading it by hand, hauling it in ox-drawn carts, starting in the wee hours of the morning. Only by working no less than fifteen hours a day could they complete the task.

And today there are no Cubans in our fields who, except in cases of trying to reach a goal or fulfill a pledge, as a matter of honor—such as these comrades here, these Heroes of Labor…. The reasons why our workers’ put forth extraordinary efforts are not the same as in the past, when they were spurred by hunger and death, for now they are motivated by their sense of honor. [Applause]

The unquestionable fact is that the former motivations are not, nor could they in any way be, parameters of work. Neither could the Revolution simply say to the people of Cuba: “Continue working sixteen and seventeen hours a day while the country attains development.” Even if it were theoretically possible to keep that up, from the political point of view it would be entirely advisable to send any government official who tried to put such a measure into practice to the insane asylum.

Let us not forget that in the beginning we were just a rebellious people, emotionally revolutionary, but very confused regarding political and social problems, and thoroughly indoctrinated by imperialist newspapers, magazines, films, books, and other media.

Let us not forget it and we affirm it, not with any feeling of shame, but rather with pride. And as proof of what a people is capable of achieving, as proof of the possibilities of a revolution, we must say that in 1959 the majority of our people weren’t even anti-imperialists. There was no class consciousness. Only class instinct, which isn’t the same.

It is necessary to recall that the first years were the years of great political and ideological battles between the capitalist road and the socialist road, between the proletarian path and the bourgeois path, and the task facing the small revolutionary vanguard was above all to gain the awareness of the masses. [Applause]

No one spoke of production then—the capitalists were the ones concerned with production—nor of data or statistics or structures. The problem was the needs accumulated as a result of unemployment, exploitation, abuse, and injustice of all sorts.

The battle against the enemies of the Revolution was waged in daily events and on the ideological battlefield.

So there have been not only quantitative but also qualitative changes in the needs. And we must continue to carry out tasks like that of the harvest and still in conditions of manual labor. In these years many lifelong cane cutters retired, and many other Cubans who had formerly worked fifteen or sixteen hours a day shifted to other activities. And nobody was going to stop them. Nobody could stop them. No revolution could tell a man: “You are doomed to spend the rest of your life in this work, without hope of learning to operate a machine or of working at something else.”

And these tasks are carried out today, not by those who in the past had to do them in order to avoid dying of hunger, but in the great majority by workers from industry and other services, students, and soldiers.

And we said that in these new conditions the tensions become evident, and in these conditions we waged the heroic battle. But we were unable to wage the simultaneous battle.

This term was much used before the ten-million-ton harvest, and while the cane for the ten-million-ton harvest was being planted. It referred to our need to carry out that indispensable effort that, as we explained on one occasion, was required not as a sports activity but for basic needs of the economy, for our development, to overcome and climb out of our poverty.

Let us not forget that in spite of everything during these years we have had an unfavorable foreign trade balance, mainly with the Soviet Union. Let us not forget that we must import more than five million tons of fuel, a product we must import because oil exploration and discovery and putting oil wells into operation requires detailed study which can’t be carried out from one day to the next. We are a country without coal, and practically without hydraulic energy. Our rivers are small and best adapted, under the conditions of our climate and other circumstances, to irrigation.

We import all the energy for the lights we use, for every lathe that moves, for every machine and motor of every kind. This energy replaces man in all kinds of activities; it powers cane-conditioning centers, moves machines, satisfies essential needs.

We have never found a single citizen who says: “Why so much light? Why not reduce the light?” But rather citizens who say, “There is no electricity; we want more electricity; we need power plants; we need this and that; we need machinery; we need transportation; we don’t have this and we don’t have that.”

And even so, we import more than five million tons per year plus the wheat we consume and the raw materials we use in many of our industries and the machinery we need. And we have been investing somewhat more than we have produced.

I repeat that we were incapable of waging what we called the simultaneous battle.

And actually, the heroic effort to increase production, to raise our purchasing power, resulted in imbalances in the economy, in diminished production in other sectors, and, in short, in an increase in our difficulties.

Of course the enemy insisted that the ten-million-ton sugar harvest would lead to some of these problems. It was our duty to do everything possible to avoid it. And actually we haven’t been capable of doing so.

Our enemies say we have problems, and in this our enemies are right. Our enemies say we have problems, and in reality our enemies are right. They say there is discontent, and in reality our enemies are right. They say there is irritation, and in reality our enemies are right.

As you can see, we aren’t afraid to admit it when our enemies are right. [Applause]

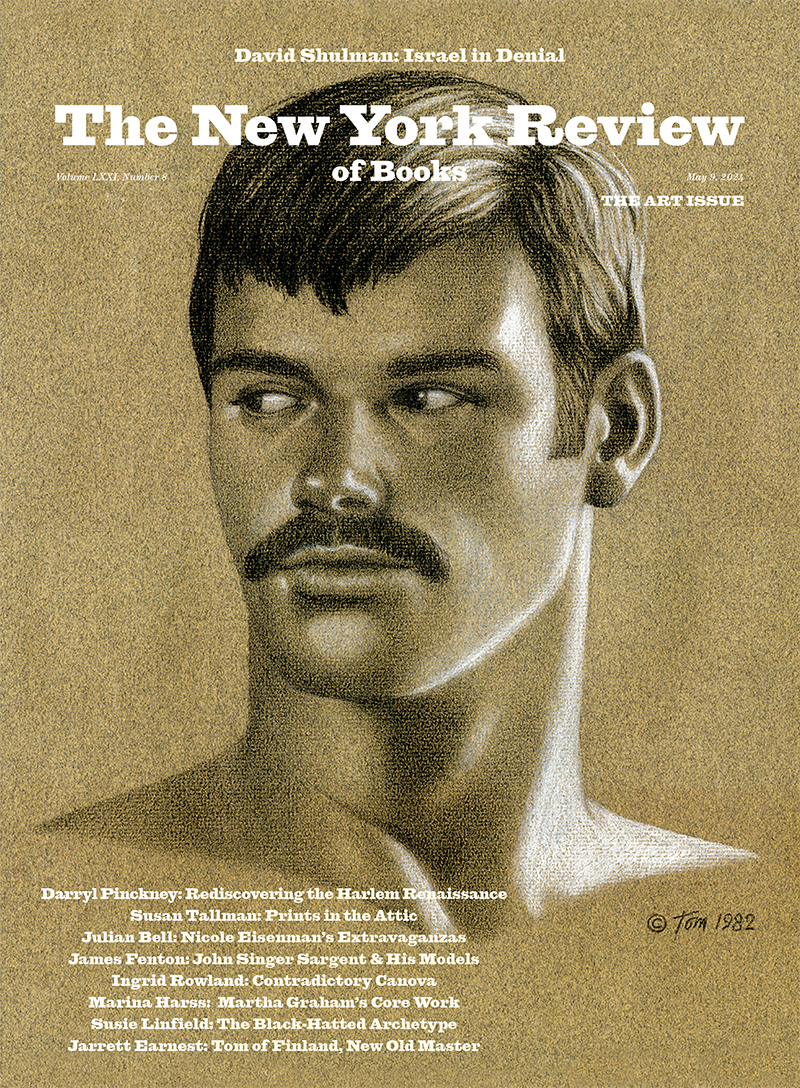

But I’m going to give more data. This that I have here is not a speech. No sir, it is not a speech. This data is part of a highly secret economic report. What I have here is not a speech but the secrets of the economy [applause], one of those things that are written and discussed in secret so that the enemy won’t learn of them. Here we have them. We aren’t revealing them for the benefit of the enemy. We couldn’t care less about the enemy. [Applause] And if the enemy makes use of some of the things we say and causes us deep shame, let us welcome it! [Applause] The embarrassment will be welcome if we know how to turn the shame into strength, if we know how to turn the shame into a will to work, if we know how to turn the shame into dignity, and if we know how to turn it into morale! [Applause and shouts of “Fidel, Fidel, Fidel!”]

Here are the secrets for the people. [Applause.]

To analyze the problems by sectors, in the agricultural field we explained the problems of sugar cane, the sugar produced, and the records that have been established.

In rice planting, there has in reality been a considerable increase in the area under cultivation, increases in production; but we are a long way from being able to be satisfied yet, both in quantity and in quality, with the advance of our rice plans.

In pastureland, as of June 15 some 92,300 acres had been planted, equal practically to the amount planted throughout 1969. There are almost 175,600 acres in preparation, so we can say that this year’s planting should top the 330,000-acre mark, which will reverse the decreasing trend in the amount of available pastureland that we have been feeling in the last few years.

Meat. Deliveries of cattle on the hoof to the Meat Enterprise have been similar to those of 1969. Average weights have been low. Thousands of head: 485. That is, in 1968 there were 485,000 head; in 1969, 466,000; the trend in 1970 indicates the figure will also be around the 466,000 mark. In thousands of tons: in 1968 it was 154,000; in 1969, 143,000, and this year is expected to be about 145,000.

Average weight: In 1968, 697 pounds per head: in 1969, 675 pounds per head; in 1970, 682 pounds per head.

The shortage of fattened cattle and problems of transportation have produced distribution delays in the provinces of Oriente, Matanzas, and Havana.

And that is not all. The effort made in regard to pasturelands, which, as we stated, is on the increase, is not enough. A tremendous effort must be made to increase the number of calves born; likewise, a tremendous effort must be made to create pasturelands for regular grazing and for cattle fattening, for unless such an effort is made the result may very well be a reduction in the herds—because in a growing population it is imperative not only that every cow, or as many cows as possible, give birth to a calf, that the maximum number of calves reach maturity, but that all reach maximum weight in the least possible time. Otherwise the consequences may be that a cattle population that increases as a result of the nonsacrifice of cows may have to be reduced to avoiding cutting levels of meat consumption. And, of course, every effort, every possible effort, must be made to avoid this!

Fresh milk output from January through May is 71.3 million quarts, a 25 percent decrease compared to the same period in 1969, which was 95.1 million quarts.

This output drop occurs in both state-owned and privately owned sectors, but is relatively greater in the latter. This decrease is a result of the limited number of installations and of nonreplacement of dairies which were taken out of production, such as the old palm-thatched dairies.

Our milk potentials are not being fully exploited due to a lack of installed capacity.

Therefore, the milk problem is no longer a matter of the number of cows and heifers with potential milk-producing capacity, but rather a problem of installations for handling milk output.

This output decrease has made necessary a notable increase in powdered milk imports from the freely-convertible-currency area in order to meet consumer demand within the established limitations.

These imports, for 1970, amount to 56,000 tons, at a cost of close to twelve million dollars. Similar imports are planned for 1971. Imports of saltless butter also result from this decrease in milk output.

Fishing. Although the fishing plan for the first half of the year was only 78 percent fulfilled, this represented approximately 8,000 tons over the catch for the same period in 1969.

Cement. The amount of available cement as of July is slightly over that for 1969, and 23 percent less than the figure for the same period in 1968 due to difficulties in the transportation of sand and movement of the finished product.

Steel bars. Deliveries as of June were 38 percent under the figure for 1969 due to lack of transportation. On June 30 there were approximately 25,000 tons in the yards of the Antillana de Acero steel works. Nearly 60 percent of the first semester’s [six months’] production is lying still there in the steel plant’s yard.

Fertilizers. This refers to the fertilizer that is mixed here. The production plan shows a 32 percent delay, that is, 130,000 tons, originated mainly by limitations in transportation of the finished product.

Farm machinery. Deliveries to the agricultural sector included in the national farm machinery production plan have been fulfilled only by 8 percent as of May.

Nickel. According to the plan, exports of this product represent 217.8 million pesos in 1970. As of July, the plants in Nicaro and Moa have fulfilled 96 percent of their plan for the first half of the year. Therefore, there has been no problem in general in nickel production. There are no problems, either, in regard to fuels and lubricants, that is, in the refining industry. That sector is meeting its plan.

Electric power. Electric power output as of May was approximately 11 percent above that for the same period last year; at the same time, there was a high increase of roughly 17 percent in maximum demand.

In other words, electric power production has increased by 11 percent while the demand has grown by 17 percent.

The existing deficit in relation to maximum demand results in power interruptions—which will tend to become more frequent—caused by a shortage in the manpower needed for maintenance service and delays in the installations of new generating capacity.

The manpower shortage has an adverse effect on the laying of power lines and the construction of power substations. The installation of the 220-kilowatt Renté-Nuevitas power line to Holguin does not look as if it will be concluded by the end of the year, as had been planned. In other words, it may take a few months longer.

Rayon. In view of the critical manpower situation it has been necessary to cut down production plans, a measure which has principally affected the manufacture of tires. Reconditioning of the plant will be begun shortly for completion this year.

This plant, which is very important to our economy, the base for the production of tires which, in turn, are essential in such a critical sector as transportation, is facing a special kind of problem: contamination of the environment by sulfocarbon, as a result of the chemicals utilized in the plant.

What was the picture in the past? In the past, contamination was three times as high as it is today. Nowadays, the contamination has been cut down to one-third. However, the owners and managers of that plant kept quiet about the harmful effects of sulfocarbon upon the workers’ health. And yet many people wanted to work there, and considered the work a good, well-remunerated job. Today there is no secret about the contamination because a revolutionary management cannot deceive the workers. Efforts were made to reduce the degree of contamination, and it was cut down to one-third.

But it is not easy to keep workers on the job even by rationalizing working conditions, which is feasible, by not prolonging the stay of workers in the plant beyond an established number of hours, rotating them from one department to the other, and other measures. That is the plant that is allotted the best food and the largest amount of food in our country. So the difficulties there do not stem from mobilization to the harvest but rather from this special problem. And investments of more than one million pesos are being made in imports to totally eliminate the phenomenon of contamination by sulfocarbon. But the fact remains that this phenomenon has had an adverse effect on an important plant.

Paper and cardboard. Production has been affected in the amount of 5,900 with regard to the plan by limitations in the supply of bagasse and by delayed reception of imports of aluminum sulfate and caustic soda. The fulfillment of this year’s plan depends on the transportation of 30,000 tons of bagasse from Camagüey to the paper manufacturing plant of Damuji and the arrival of the caustic soda. In turn, difficulties in the transportation of products from the paper manufacturing plant to corrugating plants have led to non-fulfillment in the plan for the production of cardboard boxes—which, in turn, has an adverse effect on the production of condensed milk, beverages, paint, pharmaceutical products, etc.

Bottles. Production has been affected by manpower problems and by difficulties in the transportation of raw materials to the various plants and of removal of the finished product. Imports of some two million dollars in convertible currency have been made to make up for insufficient production of medicine bottles. Larger imports are foreseen for 1971.

Tires and batteries. The tire production plan will fall short by 216,000 units, that is, 50 percent of the plan. Of these 150,000 are tires for passenger cars. Deliveries to the shipping agency for light cargo transportation will also suffer. This is due to the reduced supply of rayon cord which, in turn, stems from problems in the rayon plant in Matanzas. In addition, irregularities in the arrival of imported raw materials have obliged us to make changes in the formulas to the detriment of the finished product.

Naturally, not all the tires used in our country have ever been produced here by any means. Large numbers are imported. But the adverse effects on the production of tires are felt.

The production of batteries is also 33 percent—approximately 16,000 units—below the aggregate plans as a result of delays in the delivery of lead oxide and casings. The low percentage in the recovery of casings—and the bad condition of these casings as a result of excessive use and the bad condition of the equipment—has also had an adverse effect on the fulfillment of the plan.

Leather footwear. The plan for this year was scaled down from 15.6 to 13.9 million pairs. As of May, production had fallen short by approximately a million pairs, due to delays in the start-up operation of a new factory in Manzanillo, absenteeism, and mobilizations for agricultural work. Some 400,000 pairs of work shoes and boots are included in this production lag. Moreover, there has been a deterioration in the quality of this footwear, due to changes in the technological process and the time needed for the curing of the hides.

Together with this, it should be pointed out that the factory that is turning out plastic footwear is nearly in full production, and no fewer than ten million pairs will be manufactured within the next twelve months. This will be a considerable aid in supplying the demand for women’s and children’s shoes. Such is not the case with men’s work shoes or with closed shoes, because the material being worked with is still impermeable. There is a type of material being analyzed, called polyurethane, of which shoes can be made, and its technology is already being studied.

These machines were acquired and installed in a very short time. They are run by 300 workers—the overwhelming majority of whom are women—and these 300 workers will produce some 12 million pairs of shoes a year. In Santiago de Cuba the foundations are being laid for a similar plant. So that, while 600 workers—the majority of whom are women—in four shifts…because it must be pointed out that this plant already has, on a test basis, due to its great productivity, a shift system according to which the women who work the midnight shift are only required to work five hours.

The longest shift is seven hours; the shortest, five; and there are two six-hour shifts. That is, there are two six-hour shifts, one five-hour shift, and one seven-hour shift. Six hundred workers—almost all of them women—with these machines and this chemical product will produce 24 million pairs of shoes a year. At present, all types of footwear considered, some 19,000 workers produce between 18 and 19 million pairs. This is perhaps indicative of the way—the only way—to solve the problems to which we have already referred.

Fabrics and garments. As of June, there was a production lag of 16.3 million square meters, due principally to a labor shortage, which was aggravated by mobilizations for agricultural work. This implies an adverse effect on the supply of textiles for personal and domestic use, which, in turn, caused delays in garment manufacture and resulted in a reduction in direct distribution to the population. The delays in garment manufacture are mainly in children’s school clothes, men’s underwear, sheets, pillowcases, and dresswear.

Toothpaste. Eleven percent of the production plan has not been met, mainly due to a lack of aluminum tubes, because of the mobilization of workers to agricultural work.

Soaps and detergents. There is a 32 percent lag in the production plan, due to transportation problems abroad with raw materials such as dodecilbenzene and delays in the shipment of caustic soda.

There has also been a delay in the production plan for soaps, due to delays in shipments of raw materials and a lack of transportation facilities abroad for purchases made in the capitalist market.

Bread and crackers. In Havana bread production is 6 percent below plan for the first semester of this year and 2 percent below the first semester of 1969. This is due to absenteeism, breakages in the bakeries, and power shortages. Cracker production has been affected primarily due to mobilizations for agricultural work.

Consumer levels. The following increases in distribution have been recorded. Rice: the quota was raised to six pounds per person per month throughout the nation for home consumption in April and for state agencies in January. Fresh fish: the supply to the population was increased in April. Eggs: there was an indirect consumer increase.

Nevertheless, there has been a considerable restriction and decrease in other consumer goods: root and other vegetables, fresh fruits and fruit preserves.

Meat and poultry. Consumer levels have been restricted, due to certain priorities, and, furthermore, there have been delays in distribution to the population, due to transportation problems.

Beans and edible fats. There has been a slowdown in distribution, due to delays in imports, difficulties at the ports, and internal transportation difficulties. Soft drinks: there has been a decrease in the supply, due to a shortage of bottles. Beer and alcoholic beverages: there has been a decrease in the supply, because of a slowdown in bottle return, due to limitations in the consumer network and the accumulation for the July festivities.

Cigars and cigarettes. An increase in the demand and a shortage of tobacco have been responsible for the rationing of these products.

There have also been difficulties in the distribution of industrial products such as detergent, toothpaste, textiles, and clothes of all types, including underwear.

Foreign trade. In our foreign commerce we are faced with a nonfulfillment of export and import plans due to the following: delays in contracts; difficulties in securing ships to move our import and export cargo; a critical situation in loading and unloading at the ports.

The aforementioned has been responsible for the following: problems in the transportation of equipment coming from Europe; delays in the importation of raw materials and foodstuffs; ships delayed in port. Market difficulties in the convertible currency area with regard to the buying of wood pulp continue to affect the production of containers. That is, even with ready cash wood pulp is difficult to obtain. Although purchases for 1971 and 1972 have been authorized, we have yet to find the necessary supply.

Situation at ports of entry and internal transportation. The volume of dry cargo handled in our ports from January to April is 20 percent over the corresponding period for 1969. The number of ships in our ports is increasing and this situation will become more pronounced in the present month of July when 450,000 tons of cargo are expected—a greater volume than in previous months. From March to the present moment the aecumulation of cargo in our ports has increased from 100,000 to 140,000 tons on the average.

The mechanization program now being carried out should have a favorable influence on the solution of operational difficulties. Special attention must be given to the buying, building, and reconditioning of barges and tugs to ensure the shipments of sugar and molasses contemplated in export plans for 1971. To this must be added dredging, reconditioning, and building of important port facilities.

Internal transportation. Difficulties have been encountered in highways as well as railroad transportation. These difficulties have been determined partly by the priority given to the transportation of sugar cane and by-products, and partly by a lack of spare parts. The result has been a decrease in the number of available vehicles, which has led to operational problems and seriously interfered with economic activities during the period.

From January to April of this year there was a 26 percent increase over the corresponding period last year in the volume of freight hauled by rail. During this period sixty locomotives (27 percent of the total number) were used for the transportation of cane. In transportation by truck the main difficulties, have been due to the lack of spare parts and the high level of absenteeism, which has been one of the highest in recent years.

The following were the most important difficulties caused by internal transportation problems: delays in receiving trains with cattle from Camagüey and Las Villas, which resulted in a loss of weight in the cattle; nonfulfillment of the lard distribution plan and nonfulfillment of the plan for bringing milk bottles to the provinces. Practically all the beer, milk, and other bottles which are not imported are produced in the western part of the country, as is all the nonimported cloth. This requires shipping all this material east. Bottles for all the beer made in Oriente are produced in the western part of the country, in Havana.

Industrial goods pile up in the provincial warehouse of the Ministry of Domestic Trade in Havana. The plan for transportation of raw materials used for soaps and detergents, as well as the finished product, was not fulfilled. The transportation of silica sand for the production of cement and bottles, the transportation of steel bars, the transportation of fodder for the animals on state farms, and the transportation of bagasse for the paper factories in Las Villas were insufficient. There was a work stoppage in the nail factory in Santiago de Cuba due to a lack in the transportation of raw materials; and the national fertilizer production plan was not met because of low extraction of the finished product. There was a 36 percent drop in the number of railroad passengers, compared with 1969 in the January-May period, caused by the transfer of locomotives to the sugar harvest and the withdrawal of coaches from circulation due to lack of spare parts.

We have outlined the main difficulties in agriculture and industry. And the list, of course, is not complete.

There are worse difficulties—which have been growing worse for some time—in certain services to the population such as laundries. They are part of the limitations we have discussed here, and there are others we haven’t mentioned.

This statistical outline contains only a part of the cause. We must say that inefficiency, the subjective factor, is partly to blame for these problems.

There are objective difficulties. Some of them have been pointed out. But we aren’t here to discuss the objective difficulties. We must discuss the concrete problem, and man must contribute what nature or our means and resources have not been able to provide. It depends on man. Men are playing a key role here and especially the men in leadership positions. [Applause]

We are going to begin, in the first place, by pointing out the responsibility which all of us, and I in particular, have for these problems. I am in no way trying to pin the blame on anyone not in the revolutionary leadership and myself. [Applause] Unfortunately, this self-criticism cannot be accompanied by other logical solutions. It would be better to tell the people to look for somebody else. [Shouts of “No!”] It would be better, but it would be hypocritical on our part.

I believe that we, the leaders of this Revolution, have cost the people too much in our process of learning. And, unfortunately, our problem—not when it is a case of the Revolution; the people can replace us whenever they wish—right now if you so desire! [Shouts of “No!” and “Fidel! Fidel! Fidel!”] One of our most difficult problems—and we are paying for it dearly—is our heritage of ignorance.

When we spoke of illiterates we didn’t include ourselves among the illiterates, or even among the semiliterates. We could best be classified as ignorant. And we were ignorant—almost without exception (and I, of course, am not the exception)—all of us. The problem is even worse. Signs of illiteracy or semiliteracy can be found in many men in positions of responsibility and one of our most serious problems is the one we face when we go looking for the man to fit the job.

A few days ago, gathered in Céspedes Park in Santiago de Cuba, after having visited several factories one by one and having talked with thousands of people, we discussed the problems of each and every one of the industries in detail.

There was a 50,000-ton drop in the production of the Titán Cement Factory because its storage areas were full, while in the city of Santiago de Cuba—as in the other cities of the country—there was a tremendous demand for cement to repair homes.

There was a 6,000-ton drop in the production of the flour mill—a factory which had been enlarged—because the flour which had been produced wasn’t removed and the factory had to shut down, which meant that a town might be left without bread, for lack of flour. And we had the wheat to produce the flour, and the workers and machines. The harvest wasn’t to blame; the harvest resulted in some problems, but not all. I am giving you a few examples.

With the best of intentions, a concentration of transportation was carried out which proved to be excessive. These plants had to depend on an operative base.

There were problems in the cement industry with quarry equipment. We spent hours talking with the equipment operators about a series of specifications, calling on their experience and hearing their ideas so that, given the resources which will enter the country this year and those already available…. All the complementary equipment, plus a surplus to put the factory at peak capacity is on its way to the Titán Factory. Quarries require excess capacity, since an attempt to save can result in underutilization of the investment of millions of pesos in the industry and the work of hundreds of workers.

We reviewed the problems of the Hatuey brewery, the beer and malt beverage factory. Transportation is a serious problem there. Oriente turns out beer and malt beverage for internal consumption. The bottles come from this part of the country: there are delays in transportation and even in the return of used bottles. Since many of these products were distributed through grocery stores and not through public centers the bottles delayed longer in returning here and the problem grew worse. In Santiago de Cuba 5,000 or 6,000 cases were being produced; there was a drop of 300,000 cases a month: 7,500,000 bottles of beer and malt beverage which could have been consumed by the people during these months.

We analyzed the problem and realized the need for new methods, such as distribution in tank trucks. This method is already in use in some places. These tanks have a refrigerating coil and compressor and one-half horsepower for storing one hundred cases of beer or malt beverage that can be transported in a six-ton truck with a 3,000-quart tank, and even a bit more. A Zil 130 can take the equivalent of 1,000 cases on a single trip in this form.

Today we can take beer in tanks to workers’ dining rooms, recreation centers, and schools, saving the bottles, cases, and all those other things. Although, logically enough, a certain amount must be bottled for home consumption. But production increase at that factory can be still further stepped up.

I asked Comrade Risquet [Minister of Labor] to go there with the comrade Minister in charge of the Food Ministry to look into expansion possibilities. We have the raw materials: the barley, malt, even the rice, which is being used in a proportion of 30 percent in beer production with excellent results in quality. In the malts, in addition to the barley, rice, and sugar. Beer, of course, requires hops.

With relatively few investments the production of beer and malt beverages can be increased by 50 percent in Santiago de Cuba.

And today we don’t produce for profit; we produce for the people. We produce to satisfy the needs of the people. And if this production can be increased so that more workers, students, youths, and families can drink more malts and beer, with a relatively minor investment; if we can distribute them, why not do so?

We visited many centers. The repair shops…. There are problems at the Santiago Bus Terminal with the maintenance of the Skoda buses. There are 103 buses in Santiago and almost thirty-five in service for a city with a population of almost 200,000. With the arrival of the interprovincial Leyland buses, it will be possible to release other buses which should be in Santiago de Cuba on or about the fifteenth of August.

Comrade Faure [Minister of Transportation] told me that they could be there by August 5, and we would have fifty-three instead of forty of these buses available. This will help in easing the situation. But it will be especially eased to the extent that the repair shop improves and repairs are speeded up and adequate maintenance service be given to the buses.

In many industries we detected the following problems: lack of lathes, lack of work tools, lack of measuring instruments.

It’s curious but microinvestments are what our country needs most at this moment, microinvestments! Investment in lathes for maintenance in industrial shops, work tools that are lacking in almost all industries, and measuring instruments.

How did we find the spirit of the workers in Santiago de Cuba? Knowing their many needs—because if transportation affected distribution anywhere, it affected it in Oriente, and especially in Santiago—their main concern was production. And only later in the discussion did they raise any other problems! And sometimes we were the ones who had to bring up the other problems!

And sometimes we saw workers with torn clothes, or shoes—we have seen this—because these problems of quality…. It wasn’t so much the quantity as the quality of the footwear: the introduction of a new method of production which hadn’t been sufficiently grasped, such as those rubber soles which led to their breaking. And the cane cutters in Oriente and other areas know very well how a sole can fall off after five or ten days.

And when quality is affected, what is the point of making thirty million pairs of shoes, if it doesn’t solve the problem?

The problem of footwear was seriously affected by the decline in quality.

And workers with torn shoes and clothes were asking for lathes, machine tools, and measuring instruments—more concerned about this than with their other problems. Even in spite of the bad food supply, they were more concerned with the factory and production than with food. [Applause] And this is really impressive! This is a real lesson for us! This is a living confirmation in reality of the proletariat and what it is capable of. The industrial proletariat is the truly revolutionary class, the most potentially revolutionary class. [Applause]

What a practical lesson in Marxism-Leninism! We began as revolutionaries not in a factory, which would have been a great help for all of us. We began as revolutionaries through the study of theory, the intellectual road, the road of thought. And it would have helped all of us if we had come from the factories and known more about them, because it is there that the really revolutionary spirit of which Marx and Lenin spoke is to be found.

And that’s the spirit of the great majority! The few lumpen elements that may still exist—most of them recent arrivals in the plant—the absentees, they are of no importance. And sometimes conditions are such that the amazing thing is not that there are absentees, but rather that there are some who do come to work. And the spirit, the sense of duty that inspires those who go to work; and the scorn they feel for the lazy, those who are resting on their oars.

Go to any factory and ask the workers what should be done about the lazy ones, the ones who don’t work. If you don’t watch out, they’ll go so far as to demand that they be shot. If you don’t watch out, they’ll demand just that! But, naturally, they will not go that far. Not that they lack the desire to do it, but they realize that the thing to do is to re-educate those people through work.

Thus, we came face to face with these problems, most of which have a solution. And we must say that we are to blame for a large part of these problems and that, simply as a result of a lack of capacity….

We—I began to explain an idea to you—were holding a conversation with some people from Santiago de Cuba in the city’s park following a three-day visit. We were talking about these problems with them, and we asked the people there, “Do you know of someone who is efficient whom we could entrust with some of these tasks?” That is what we asked the people, because the tragic thing, one of the many tragic things in our country—and this should not, by any means, constitute a reason for resigning ourselves to putting up with this tragedy—is our lack of cadres, of men with a high enough level of training and intelligence who are capable of carrying out the complex tasks of production.

These tasks are apparently easy. Most of the time we make the mistake of minimizing the difficulties, of minimizing the complexity of the problems. And we have seen this happen to a number of well-trained comrades, comrades well known to us for their iron will and their desire to do a good job—we’ve had these experiences—and we have seen them, in a specific task, going through what is practically an apprenticeship that lasts one, two, or even three years before they begin to do an efficient job.

If only we could solve our problems by simply replacing these men! We have to make changes. There is no question about the fact that many comrades have worn themselves out, have “burned themselves out,” as they say. There are some who have had to pay for the errors committed by others, because sometimes the error points to somebody who simply cannot do anything to solve the problem.

For example, we found that, in spite of the tremendous demand for housing and for repairs to houses everywhere—and especially in Santiago de. Cuba—the comrades in the districts of the local administration and the Party don’t even have a truck or a concrete mixer with which to face such demands.

As I said before, the cement factory there would stop operating. And, while the cement plant just outside Santiago de Cuba was shut down, Santiago was suffering from a cement shortage.

It was established that a certain percentage of the cement production be earmarked for Santiago and, in addition, that whatever amount of cement that the state agencies—due to problems in transportation or plan nonfulfillment—weren’t going to take away would be delivered to the city. This is easy, for the same trucks that are used for the hauling of the raw material from the quarries can be used to deliver the cement to Santiago. And there is one problem: once the cement is taken out of the silos and put into bags it cannot remain in the bags for more than three months. That is why, when the silos are full, we can’t just say, “Let’s pack the cement in bags for storage.”

These comrades were shown how to solve the problem, since, for any repair work, they are dependent on an operational base of trucks—which they didn’t have.

You cannot hold a man responsible for anything unless he is in a position where he can decide things; or else we appoint a man from the Party, we give him a job involving responsibility, and what we do is turn his job into a man-killer. He becomes a wailing wall, a poor man on whose lap everybody and his brother dumps his problems.

There are lists of houses to be delivered. There are lists, yes, but no houses. There are very few of them, or a plan for house building hasn’t been completed. Thus, a worker who has headed the list for a year and a half and still has no house—and this has happened in Santiago—even loses all hopes of ever getting one.

As we talked with the women comrades of the beer and malt beverage brewery and the bottling plant in Santiago, we realized that nine out of ten women—nine out of ten!—mentioned the housing shortage as one of the most pressing problems. The women felt this more than the men did.

This was something similar to the problem as to whether malt beverage or beer should be served at the workers’ dining room. The women, logically, said malt beverage, while the men, also logically, said beer.

In the analysis of recreation centers…. What happened in Santiago? Every single bar was closed because of the cane harvest. The result was a kind of prohibition. As a result, the people started to make rotgut and mix it with other things, and they came up with some sort of product.

Really, we don’t feel that was necessary, and it should teach us a good lesson. Because what has here been suggested and what we have been saying since the revolutionary offensive is that it is no crime to have a beer or some other alcoholic beverage; what we were against were those dark, dingy joints where having a drink or anything was a big mystery. The Revolution is not against drinking as such.

And that was done. And it is being analyzed.

We have asked the comrade in charge of this matter to analyze the question of recreation centers to decide on which days they should be open. And the workers should be consulted in the analysis of this matter. Even there we found different opinions: whether it should be two days or four days a week. And some workers said that their free day didn’t fall on a Saturday or Sunday; it came on a Thursday or Friday or some such day. And the women had a different opinion from the men.

Once we took a poll on this question, and that’s the way it turned out. So this time I told them: “Don’t rush, find out what they think and why.”

I was witness to an argument, an analysis carried out among men and women. One man, a vanguard worker whose opinion I asked, stood up and spoke. He said that a real worker, a conscientious worker, would be on time for work no matter what he did on his day off, even if he finished at 5:00 in the morning. He said that he had been working there at the factory and had gone to bed at 5:00 in the morning and had been back again at 8:00.

One woman had already said that the men would be absent from work. Another woman said that there was no labor problem but that some men would leave half their salary at home and drink the other half.

Well, that was the problem. And I told them to study everything carefully, so as to come up with a rational solution to the problem of the recreation centers, because the workers want them—especially those workers with great work spirit, workers who have spent up to eight months cutting cane, as many workers from Havana have done.

There is something I should point out: when the cane cutters from Havana were there in Oriente, the first thing they said was that they didn’t want to leave while there was any cane left; and the second thing was, with respect to the earthquake in Peru, that they were ready to go to Peru if necessary. [Applause] That is the spirit, the conscientiousness of our workers! Our workers have become much more conscientious.

Often men with no authority to make decisions are the ones who have to confront the problems.

On the other hand, some people believe that problems can be solved miraculously, that it is just a matter of replacing certain individuals.

I was saying that it has been necessary to remove some ministers and that it will be necessary to make some other changes. But sometimes it occurs to me with a certain sadness that there might be some confusion when the masses think that the problem can be solved simply by replacing individuals. And sometimes people say, “If they take this one out and put that one in….” And there are a tremendous number of government organizers and disorganizers and soothsayers.

But, of course, politics is not a game.

We must make changes, because, logically, there are comrades who have worn themselves out; they have run out of energy and are no longer able to handle the responsibilities they have on their shoulders. And we must make changes. But what I want to say is that it would be a fraud and we would be guilty of demagoguery, of unforgivable deception of the people, if we tried to make them believe that our problems are problems of individuals, if we tried to conceal the root of the matter, if we didn’t come right out and say that it isn’t a problem of an individual, group of individuals, or even teams. We believe this is a problem of the whole people! And we sincerely believe that the only way we can solve the problems we have today is by all working together—all of us—from the men in the highest positions of responsibility in the Party and state right on down to those in the most humble industrial plant and not just those in leadership positions there.

On this trip we discussed a series of ideas with the Minister of Labor. We said that we were still somewhat underdeveloped in the field of industrial administration. We explained why a factory of the people, which belongs to all the people, doesn’t even belong to its workers. A worker wouldn’t gain anything by being the owner of a cement factory together with his group, absolutely nothing at all. We have never shared that opinion.

We have seen the love the workers have for their factory—this is something else again—and believe it would be a good idea to link the workers’ everyday life—even their family problems, vacations and birthdays, lots of things—to the job. The workers’ affection for the factory would be strengthened if it were extended to tie in their families with their work. Some vacation plans have already been organized along these lines.

Some of the factories quite a way out from Santiago were assigned some of the buses that are being put together here in a shop which has greatly increased its productivity. The shop is assembling about four medium-sized buses a day. We gave some of these buses to the factories so the workers would use them at certain hours of the day. If a shift at a power plant or oil refinery winds up late at night and the workers have to try to catch a bus at a time when there are fewer buses on the streets, logically, the factory’s buses could be used to take the workers to their destination. These same buses can be used when the vacation period comes around, to take the workers and their families to the beach or other recreation areas.

The problem of housing distribution can be handled through the factories, as well. And the workers should be the ones to make the decisions. They, better than anyone else, know which worker needs a home most, or if he has a home…. He should speak about it. This problem should never be solved through administrative channels.

In the same vein, we told the comrades in Santiago de Cuba whom we have assigned the cement, trucks, and electric concrete mixers that we couldn’t solve that problem by looking for a labor force we don’t have. Urgent problems such as that of housing can only be solved with the aid of the masses!

Why? We have already explained the manpower problems we have and our problems with important industrial installations, schools, hospitals, and new factories.

Among other things, over one hundred jobs involving the installation of the equipment that is already here must be done. We could add that the installation of plants that are already here must be completed before we bring in new ones. Before we bring in new plants, we must first have all the already established ones operating at full capacity. Before we purchase new plants, we must purchase lathes for maintenance shops, tools, gauging equipment, and, occasionally, even a motor—these are what we call microinvestments—in order to get all those plants operating at 100 percent capacity, first of all—and, if possible, at 110 percent—and raise the workers’ productivity. We must also install all the equipment whose installation is still pending.

Suppose this crash program makes it impossible to organize the brigade needed to solve the problem of repairs…. What did we tell the people in a number of towns? In Caney, for instance, they said to us, “We don’t have a barbershop or a store.” And we said, “If we supply you with the materials, will you take care of the construction end?” The answer was, “We’ll do it.” The same thing happened in Mataguá, in Las Villas Province, and in Quiñones. We got the people together, and now they’re even going to build a polyclinic. Right away a bricklayer pops up from somewhere, and then another, and then still another.

They’re even going to build a thirty-bed polyclinic! They want a polyclinic? Then let them have the prefabricated sections and the equipment with which to do the job, and they’ll take care of the construction. Because the main problem is to find ten or twenty workers to build a house, anywhere. This problem of housing should be handled by the masses—repairs in some cases, construction in others.

And we used to say to our comrades, “Whenever there is repair work to be done, never decide what’s to be done by yourselves; let the neighbors decide, for only they have the right to decide, with their spirit of equity and justice, who needs the repairs the most.” Because, even though the decision may rest on the administration, it is subordinate to a series of contradictions and opinions and even subject to the danger of favoritism. [Applause]

Let us conserve our men, let us protect our cadres from this danger, and let’s make it a point that it will be the neighbors who will make the decisions. And if the neighbors make a mistake, they are allowed to make mistakes. It may be hard, but it’s their decision. If the workers in a factory err on deciding on a problem of that type, it is hard, but it’s the people’s decision.

Take the problem of plant management. Last time we spoke of the work of the Party, of how we had to revive the work of the mass organizations and give them a broader field. But that is not enough. New problems come up, and we must delve deeper into the matter. We don’t believe that the problems of managing a plant should fall exclusively to the manager. It would really be worthwhile to begin introducing a number of new ideas. There should be a manager, naturally—for there must always be someone accountable—but we must begin to establish a collective body in the management of each plant. A collective body! It should be headed by one man, but it should also be made up of representatives of the advance workers’ movement, the Young Communist League, the Party, and the women’s front—if such a front can be organized within the plant.

We must remember that, in a factory, we cannot appoint the Party Secretary to the post of manager—there are certain things on which we must have a clear understanding—nor can we appoint the manager as Party Secretary. This is because, if he devoted his time to the task of production, he wouldn’t have time for anything else. The plant works with machines that handle material, and the Party works with men, handles men. The Party’s raw material are the workers, and the management’s raw material is just that—material. It could be iron or any other material. Each shop has its own laws, and that shop must be attended to; somebody must always be concerned about it. These tasks must not be confused, and the Party should not be held responsible for the management of the plant.

The Party’s responsibility should be an indirect rather than a direct one. It is the Party that must immediately call the attention of the superior administrative body to any deficiency, any error of an administrative nature, but the Party should never tell the manager what to do. The functions of the head of the Party nucleus and those of the manager—or, rather, of administration—should be clearly defined.

Why should a manager have to be absolutely in charge? Why shouldn’t we begin to introduce representatives of the factory’s workers into its management? Why not have confidence? Why not put our trust in that tremendous proletarian spirit of men who, at times in torn shoes and clothes, nevertheless keep up production? [Applause]

And we’ll have to work seriously on the problem of industrial efficiency, based mainly on labor productivity.

There can be the case of two factories, in one of which the workers seem to have attained higher productivity, due to the fact that that plant is better equipped technologically and its work force is more highly trained; while another factory, working under different conditions and apparently with a lower productivity per man, may be putting forth a greater effort.

Why do we mention these problems to our workers? Because there is something that is real and crystal-clear: Arithmetically speaking, the account does not jibe nor can it jibe. Those figures we mentioned in connection with our population growth, the age structure, the basic services that cannot be curtailed except at the cost of paying a terrible price for it in the future. Nonetheless, with all our inefficiency, we must solve those problems that we mentioned…. We must win the battle against inefficiency! We must win the battle against those difficulties!

An effort of a subjective character—we were saying—has to be made by all the people.

These days it has been satisfying to see the people enjoying themselves. They certainly have earned it. We wouldn’t want any worker’s vacation to be spoiled by this analysis we are making here. We wouldn’t want that at all. At the same time, we are very aware of the fact that there can be no rest for us. Those of us who have major responsibilities cannot take a rest.

To tell the truth, we have wished for the eighth or the tenth [of August]—when all activities will be resumed—to arrive. Deep down in our innermost feelings we have wished for the day when we’ll begin tackling those problems. This is not the first time we have had to face our realities.

The comrades here have given me a certificate for something that I don’t think is important at all. We actually cut the amount of cane the certificate says we have cut. But there are other comrades who went to the cane fields at the cost of much greater sacrifice than we did. Our Comrade President also worked in the cane fields many times [applause], often despite health problems. This is not to say that our Comrade President’s health is not good, but many times he went to the cane fields while suffering from backache. [Applause] Of course, we know of a great many other comrades who went to cut cane even being ill. Having cut the amount of cane we cut carries no special merit—it rather served as a diversion. Perhaps the hardest thing for us about cane cutting is not the physical work but having to do it while thinking about so many problems. During the first few days the hardest thing was to keep from thinking about the problems until we began to more or less control our thoughts.

The fact is that we would have liked to cut a little more cane than we did. We had had the illusion—as it were—that we would work four hours daily in the cane fields all through the harvest, that we could live the utopia of dividing our time between mental and physical work, which is a most healthful thing. As you can see, our pace was good, but as of January 9 the thing came to a stop. As a matter of fact, we hadn’t given any thought to the idea of winning a certificate. We rather thought of the scores of thousands of men who were making the effort and we had wished to share somehow the effort they were making. That’s why we had wished—had had the illusion, if you wish—to cut cane all harvest long. But then the problems began to appear: the problems of low sugar yield, transportation, and those connected with the mills. Then began a truly anguishing battle that went on day after day without letup: the battle of the sugar harvest in the face of a reality that was becoming increasingly evident.

In reality we have some debts pending with irony, with the illusion we have indulged in at times. We have some debts pending with our needs. We have debts pending with poverty. We have debts pending with underdevelopment. And we have debts unpaid with the suffering of the people: every time we hear a mother say that she has twelve children sleeping in one room, that the children suffer from asthma, that they suffer from this and that. Every time we see people suffering and asking for help, when we face the realities of life, we wish we were a magician and could pull the solutions out of a hat. But this country faces the reality that we need a million new homes before all families can live in a decent house, one million!

And how much is needed to build a million dwellings! How much sand, cement, and other building materials!

We have been enlarging our plant capacities to that end. We mentioned the Titán cement plant, but we must also mention the one in Mariel; we have to finish building the Siguaney plant and the one in Nuevitas. We must finish those plants any way we can and begin to produce cement at the earliest possible time, supplying them with everything they need, including an adequate work force. And if we don’t have enough workers to build houses, if we have the necessary building materials we can work with the people’s participation in many places and in others with the brigades that put up prefabricated dwellings…. The problem of productivity in home building has to be solved through those brigades.