Practically from the start of industrial manufacturing, gawkers appeared to marvel at the sight. The cotton mills of sooty Manchester were an obligatory stop for every clued-in visitor to that city. In the summer of 1915, Henry Ford’s Highland Park factory in Michigan, the first with a continuous assembly line, drew three to four hundred visitors a day. So prominent a feature of the industrial landscape were factory tourists that Diego Rivera painted them into his mural sequence Detroit Industry (1932–1933). In one panel, the throngs at Ford’s River Rouge plant (young, old, women, men, Dick Tracy among them) look on, their mouths downturned, as the line of chassis—pierced by steering wheels and ministered to by bent-over, jumpsuited workers—rolls by. In 1971, 243,000 people visited River Rouge. Later that decade, the Commerce Department’s USA Plant Visits, 1977–78, a compendium of factories that offered tours, ran to 153 pages.

Although American manufacturing output today is near a historic high, the percentage of manufacturing jobs drifted steadily downward in the decades after World War II, and then in 2000 plunged sharply. Factories currently employ less than 8 percent of the American workforce, a consequence of offshoring as well as automation. Perhaps because there is not much romance in watching robots go about their day, the factory tour pickings are now more meager. In the Chicago area in the 1960s, you could have seen how steel, furniture, newspapers, pottery, automobile parts, hosiery, and, yes, sausages were made. Today, the only factory tours left in the city are epicurean: craft distilleries, artisanal chocolateries, and a popcorn factory. If you want to have a look at manufacturing of the Make-America-Great-Again variety in Illinois, you will need to drive nearly two and a half hours to Moline, where the John Deere company, headquartered there since 1848, still provides free tours of the harvester works.

With nostalgia for manufacturing jobs now thoroughly weaponized in American politics, Joshua Freeman’s Behemoth: A History of the Factory and the Making of the Modern World is timely. Freeman, a historian of American labor and the author of American Empire, the Penguin history of the post–World War II United States, takes as his subject huge factories, the behemoths of his title: River Rouge; the Soviet steel complex Magnitogorsk, east of the Urals; and China’s Foxconn City, with its hundreds of thousands of workers, arguably the largest factory ever in operation. Focusing on these giants, Freeman suggests, reveals what happens when concentrated production and economies of scale are taken to the showiest extreme. It also helps to explain the hold that factories have had on the imagination over the past 250 years: the promise (largely delivered on) that industrialization would lift billions out of poverty, competing with the fears (also realized) that it would wreck the environment and sharpen social conflicts.

The scholarly literature on industrialization is vast and thicketed with controversy, but Behemoth is not one of those doorstop histories of the around-the-world-in-eight-hundred-pages variety. Rather, the book is episodic, assessing the turning points that take the reader from late-eighteenth-century Britain—where modern factories emerged—to early twenty-first-century China, with most of its pages devoted to the United States and the Soviet Union.

Freeman’s account is evocative and fair-minded, a humane treatment of the subject written with flair. It is also a fresh approach to a well-established genre: the biography of an object, which tells a story of global transfer and connections. Thus far, commodities such as tea, coffee, cod, cotton, porcelain, and gold have soaked up most of the attention. Unlike cod or cotton or any of the other objects that have been nominated for world-historical significance, factories did literally make the modern world. Unless you’re reading this review in an old-growth forest, nearly everything you’re looking at now was factory-made. But as Freeman charts the rise of the factory across the world, his book also poses the question, Is the factory a “thing,” and did it have a global history?

The rise of the factory was the consequence of three interrelated developments: machinery that was so large or expensive that production could not be carried out at home, technological expertise that similarly exceeded the capacity of the individual household, and entrepreneurs who wished to directly supervise their workers. By the time factories appeared in Lancashire and the East Midlands, the transition to an industrial economy was already underway, and the task of making sense of this new system of manufactures fell first to the British. The perils were apparent: the exploitation of child labor and the thick forest of chimneys pumping out smoke and gasses, the filth of the overcrowded cities and the subjugation of workers to new forms of discipline that critics likened to slavery.

Advertisement

But just as obvious was the wonder. It was not simply about the goods produced—a quantity of textiles measured in miles rather than yards—but the factories themselves, of which Joseph Wright’s 1783 painting of Richard Arkwright’s cotton mills at night provides a glimpse. Outshining the moon in Wright’s picture is the factory, each one of its rectangular, symmetrical windows ablaze, a scene of harmonious, heavenly creation in the Derwent Valley. To describe what they were seeing, writers pressed far-fetched metaphors into service: Robert Southey thought the new factories looked like convents, Alexis de Tocqueville called them “huge palaces,” while Charles Dickens, describing the steam engine, likened its pistons to “the head of an elephant in a state of melancholy madness” and the smoke it produced to “monstrous serpents.”

If the British figure in Freeman’s account as ambivalent industrializers alarmed by “dark Satanic mills,” the Americans were gung ho. Much of the early industrialization of the US was powered by water, not coal, so early mill towns, such as the textile capital of Lowell, Massachusetts, its streets lined with tidy flower gardens, bore little resemblance to Britain’s smog-choked industrial cities. Lowell’s mill girls were by legend sturdy, apple-cheeked farmers’ daughters supplementing their dowries by superintending looms for a few years. In antebellum America it was possible, Freeman observes, to imagine that “industry and republican community could coexist.” Over time, working conditions deteriorated: Lowell’s women workers were forced to mind more looms and speed up production; strikes over longer working hours and low pay idled the sprawling Amoskeag cotton mills in New Hampshire. Nevertheless, Americans continued to be entranced by the machine, celebrating the blast furnaces and foundries of iron and steel as the engines of modern life, and the factory as the proving ground for Frederick Winslow Taylor’s theories of scientific management.

At the heart of the global history that Freeman tells is Fordism, which combined interchangeable parts, a continuous-flow assembly line (adapted from the meat-packing industry), and the conveyor belt to turn the factory itself into a vast, unified machine. Not only did Ford’s method reduce labor time—a car could now be made in ninety-three minutes rather than twelve and a half hours—but it promised higher wages (Ford’s Five Dollar Day was double what the average auto worker had earned), which would allow assembly-line workers to purchase the Model T’s they made. At its peak in 1929, River Rouge employed 102,811 workers and was the biggest single factory complex in the United States. Mass production fed mass consumption. Fordism itself became an American export: Ford’s autobiography, My Life and Work, sold more than 200,000 copies in Germany and was similarly a best seller in Russia, where it came prefaced by the statement: “Fordism is a system the principles of which have been known for long, [having been] laid down by Marx.”

In the 1910s, the American left thrilled to Ford, just as the Soviets would in the next decade, deterred neither by the rigid discipline of Ford’s plants nor by the mind-numbing nature of assembly-line work. When the radical journalist John Reed interviewed Ford in 1916, he delivered an encomium that could have come straight from the automaker’s own publicity department: “Here is a powerful industrial baron who is interested in human beings instead of stocks and bonds.” For their part, the Soviets needed to industrialize at breakneck speed, to make up (as Stalin famously said) a hundred years of development in ten. During the more market-oriented years of the New Economic Policy, the Soviets sought, unavailingly, to persuade the Ford Motor Company to build them a tractor plant. After it demurred, they instead hired Ford’s architect, Albert Kahn, to build the country’s largest factory, Stalingrad’s Dzerzhinsky tractor plant. During the Depression, Ford did agree to help equip an automotive plant at Nizhny Novgorod, a maneuver that allowed the company to sell the Soviets its obsolete tools and dies.

In comparing the gigantic factories of the Soviet Union and the United States amid the muscular pushes for greater output from the 1930s through the 1950s, Freeman emphasizes their similarities. The factory, he writes, “proved remarkably impervious to its surroundings.” In state socialism as in capitalism, social relations within the factory were hierarchical, often conflict-ridden; in both systems, management sought to craft a new sort of person: provident, modern, and well-disciplined. It was the similarities between the Moscow textile mill and Amoskeag that caught the eye of the photographer Margaret Bourke-White. For midcentury theorists ranging from C. Wright Mills to Talcott Parsons to Clark Kerr, such a convergence was a result of the process of industrialization itself, which was making societies more alike.

Freeman’s most illuminating chapter, though, centers on a difference in the lifespan of the giant factory in the US and Soviet Union. Even as social scientists and economists speculated about convergence, American manufacturers had already begun to decentralize production. By the late 1940s, the era of the showcase factory was over in the United States. The strength of unionization, particularly demonstrated by the formidable strike wave of 1945–1946, made clear to industrialists the danger of concentrating workers in a few plants.

Advertisement

More than simply a means of controlling costs or rationalizing distribution, the drive to open smaller and decentralized plants, especially in the low-wage, nonunionized South, was also a strategy to ensure that a company’s entire operation couldn’t be hamstrung by a strike. At the same time, by contrast, industrial gigantism continued apace across the Eastern Bloc. The East Germans built the steel town of Stalinstadt (now Eisenhüttenstadt); in Poland, there rose Nowa Huta, with a workforce of nearly 30,000 by 1967. Crippling labor unrest wasn’t a problem that particularly worried leaders in the Eastern Bloc, who could count on a network of spies as well as a cadre of factory workers who were fervent believers in socialism.

How to tell this epic story of industrialization around the world? Freeman in effect follows the lead of commodity history. That genre has become a staple of the new global history, thriving on evidence of networks that regionally or nationally bounded studies often neglected. The forces of global integration, too, can be illuminated by the history of a product, as recent studies of cotton by Giorgio Riello and Sven Beckert have demonstrated.1 The rage for calico, for example, drew British entrepreneurs into competition with Indian textile makers; Lancashire cotton mills helped to propel the slave economies of the American South, which were in turn financed by the London money market.

But to track the phenomenon of the factory across borders is to try to capture a much broader set of processes—the many variants of industrialization—in a thing. By comparison, commodity histories, even those that tackle manufacture, have an easier task: telling the story of trade, adoption (or adaptation or rejection), and the reorientation of sectors of economies, with a tangible object, usually a consumer good, at its core. The project Freeman sets himself is more like writing in a genre that doesn’t really exist: the global history of the schoolhouse or the farm or the insane asylum or even the parliament. The question, then, is what telling this history from the vantage point of an institution can add to what we already know about the spread of literacy, the transfer of agricultural techniques, the management of madness, or comparative democratization, respectively. Or in Freeman’s case, the coming of industrial society.

Take the issue of factory size, the behemoths on which Freeman focuses. He makes a persuasive case that the largest factories served as beacons of modernity, conjuring up either the horrors or the delights to come. But whether size mattered otherwise—in the productivity of a country’s industrial sector, its capacity for innovation, or its working conditions—is doubtful. In 1871, when Britain produced one fifth of all manufactured products in the world, the average British manufacturer had fewer than twenty workers; by the early twentieth century, the number had risen only to sixty-four. American factories on average were slightly larger, but, notably, most of the increase in the workforce took place in the late nineteenth century, well before Fordism. France had relatively few big factories, chiefly because a lack of coal reserves put a steam economy out of reach, while Germany, with ample coal, had substantially larger concerns, including the Krupp factory in Essen that employed more than 36,000 workers in 1914, even as medium-sized and small plants formed the bedrock of the economy. And yet, notwithstanding their differently sized factories, by 1914 per capita income and labor productivity were converging in the major Western European countries.

Through the 1970s, the history of industrialization was told as a tale of modernization, with the British model—a transition to steam and heavy industry—celebrated as the standard and nations such as France branded as laggards. What has since been demonstrated, contrary to modernization theory, is how remarkably divergent industrial transitions have been around the world, shaped by the availability of skilled labor, the scale of domestic markets for goods, the types of natural resources at hand, the strength of unions, and the character of the state. Mass manufacture depended upon small firms’ capacity for flexible production, just as mass markets (say for the Model T, which was produced in only one color, black) coexisted with highly segmented and differentiated markets (General Motors’ “car for every purse and purpose”).

From this sophisticated scholarship have come many surprises. In eighteenth-century Britain, Asian imports such as Chinese porcelain and Indian calicos, as Maxine Berg has argued, provided stimulus to new production processes; the global trade in commodities not only preceded mechanization but helped to propel it.2 Analyzing Japan, Tessa Morris-Suzuki has demonstrated that small-scale, indigenous manufacturing flourished alongside imported Western technologies to produce the network of subcontracting firms so characteristic of twentieth-century Japanese industry.3

In making the giant factory stand in for industrialization, Freeman loses much of this rich diversity, and as is often the case with a bird’s-eye view, everything appears much the same. A case in point is his treatment of Soviet factories such as Magnitogorsk in the 1930s: “Did socialism, or state ownership, change internal relationships within the factory? A bit, but not much.” Tyrannical as Ford’s regime was at River Rouge, though, this is simply not a plausible argument. Freeman himself notes the Soviets’ use of forced labor, the deaths from freezing cold in improvised settlements, the purges that removed the upper layer of management, as well as the zealous corps of shock workers willing to labor twelve-hour days and without pay on Saturdays in pursuit of the socialist utopia. Why should similarities be the salient point?4

It is even more puzzling when Freeman depicts the factory as an autonomous, globe-trotting agent that determined the course of development. “The giant factory shaped the path along which the Soviet Union developed,” he contends. But this is surely to get the causal argument backwards. The factory didn’t remake socialism in its own image. Rather, the form that industrial gigantism took in the Soviet Union was due to the judgment of Stalin and his allies that industrialization was a preeminent tool of class warfare, ensuring the triumph of the oppressed against the old exploiting classes. At times in Freeman’s account, the factory seems to come loose from its moorings in both the industrial economy and the wider history of globalization—the steamships, railroads, telegraph, airplanes, mobility of capital, and transnational mass migration—to resurface as a zombie of modernization theory reborn.

There is a major point to be made about the importance of the factory system in changing the nature of work. But to see the story whole requires comparing factory labor to work done in other places. While novel techniques of discipline, time management, and rationalization began in factories, they didn’t stay there. From 1850 to 1914, as Joel Mokyr has suggested, the innovations of the factory spread to the service sector, where department stores prevailed over corner shops; hospitals, not homes, became the places for treating the sick; and commuting turned into a nearly universal experience.5 Taking orders, pooling knowledge, the repetition of segmented, rationalized tasks, leaving your home to work—by the early twentieth century, what had started within the factory’s gates had transformed work outside them.

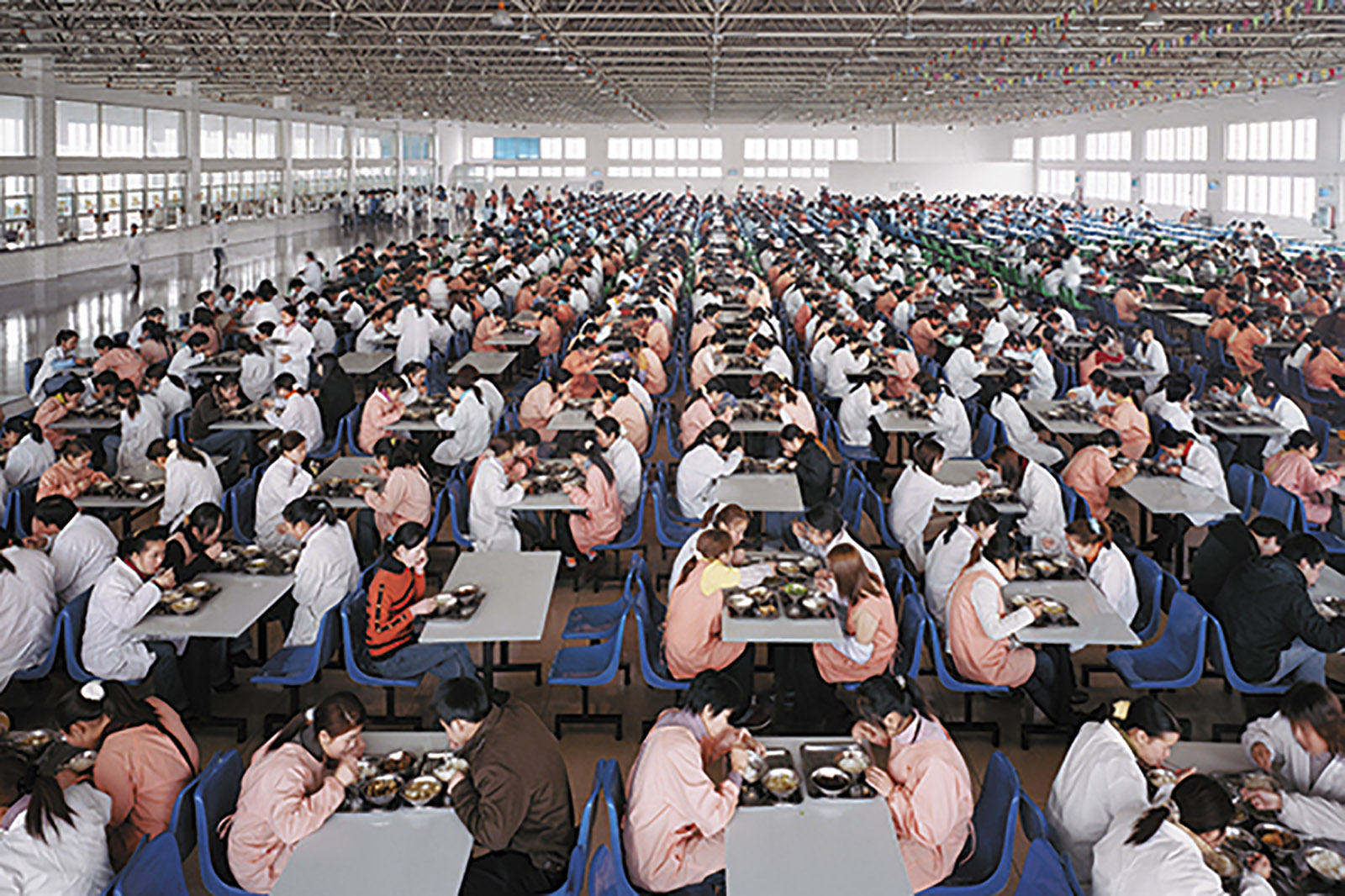

With the rise of the digital economy and automation, the question of what work is—or will be—is more unsettled now than it has been for the last century. Perhaps, Freeman suggests, we are witness to the end of the enormous factory, made obsolete more by robotics than the hectic scurry of manufacturing around the world. He ends his book in contemporary China, with a look at the Shenzhen megaplant, Foxconn City, a contract manufacturer for Apple, Dell, and Hewlett-Packard. At its peak in the last decade, Foxconn City employed more than 300,000, providing a mammoth on-demand workforce for Apple’s just-in-time production schedule. The plant’s workforce has recently shrunk as the company has automated and moved factories to cheaper parts of China.

Difficult as it is to find a factory tour in Chicago, it is harder still in China. Foxconn is notoriously secretive, a policy that undoubtedly satisfies Apple; having largely divested itself of factory workers, it is in no hurry to show off the conditions at its contract manufacturers. Foxconn City, as Freeman notes, is not a sweatshop: the plants are modern and clean, with dormitory-style housing on site and amenities such as swimming pools, a stadium, a wedding-dress shop, and pork for lunch. Foxconn pays better than the locally owned alternatives, and thousands clamor to work there. But a visit to the Shenzhen complex—wrapped in yellow netting to prevent suicidal workers from jumping off the buildings—would hardly bolster Apple’s promise through technology of untethered freedom. The discipline is militaristic, the workdays stretch to twelve hours, and the surveillance is constant. Robots, by contrast, don’t require sleep or need wedding gowns.

Although the techno-optimists won out the first time around, even those at the heart of the revolution ultimately had their regrets. In the mid-1920s, Henry Ford bought 260 acres of meadowland a mile away from his River Rouge plant. There he recreated the idealized small town of his childhood, which he named Greenfield Village, after his wife’s birthplace. Ford spent more than $10 million on this endeavor (as much as $1 billion in today’s money), purchasing a blacksmith shop, a country store, the one-room schoolhouse he’d attended as a boy, a sawmill, a weaving shed, an 1890s Detroit lunch wagon, the Wright Brothers’ cycle shop, rows upon rows of farming equipment, and a cottage and flock of sheep imported from the Cotswolds, in addition to a replica of Thomas Edison’s Menlo Park laboratory. During Ford’s lifetime, no automobiles were permitted in Greenfield; visitors came in horse-drawn carriages or, later, on foot. The point was to summon up the preindustrial age that Ford, as much as anyone, had destroyed. At nighttime, when the crowds had gone home, the old inventor haunted the village to tinker in the blacksmith’s shop.

This Issue

September 27, 2018

Aquarius Rising

Tenn’s Best Friend

-

1

Giorgio Riello, Cotton: The Fabric That Made the Modern World (Cambridge University Press, 2013); Sven Beckert, Empire of Cotton: A Global History (Knopf, 2014). ↩

-

2

Maxine Berg, “In Pursuit of Luxury: Global History and British Consumer Goods in the Eighteenth Century,” Past & Present, No. 182 (February 2004). ↩

-

3

Tessa Morris-Suzuki, The Technological Transformation of Japan: From the Seventeenth to the Twenty-First Century (Cambridge University Press, 1994). ↩

-

4

Comparing Americanization and Bolshevization, Stephen Kotkin draws an important distinction. Because nearly every Soviet town was a company town, Kotkin writes, “there was really nowhere to hide.” See Magnetic Mountain: Stalinism as a Civilization (University of California Press, 1995), p. 223. ↩

-

5

Joel Mokyr, “The Rise and Fall of the Factory System: Technologies, Firms, and Households Since the Industrial Revolution,” Carnegie-Rochester Conference Series on Public Policy 55 (December 2001), pp. 1–45. See also Mokyr’s “Economic History and the ‘New Economy,’” Business Economics, Vol. 36, No. 2 (April 2001); and The Gifts of Athena: Historical Origins of the Knowledge Economy (Princeton University Press, 2002), chapter 4, especially p. 125. ↩